On October 30th, we disappointed a valued customer. We shipped an order to them that they could not use. The extruded rod was scratched from our manufacturing process and we didn’t pack their order correctly. The parts looked bad and didn’t properly function. To top it off, this extruded shape is probably the easiest one we make—a simple round rod. Talk about shooting yourself in the foot!

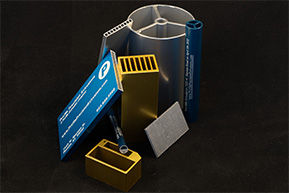

Adding insult to injury, we are working on a brand new project for the same customer. The new extruded shape is much more complex, holes are drilled, and the part is anodized. We’ve spent the past week doing exactly what we should be doing to avoid the problem with the rejected rod, which meant “doing our homework.” We’ve held three meetings internally with our production team, emailed two sets of questions to our customer, and started communicating with our vendors in order to avoid any problems.

If we had done our homework on the simple rod, we wouldn’t have a disappointed customer. The customer also wouldn’t be late in shipping an order to the end user. Halloween frights wouldn’t have started a day early.

For those of you taking notes, the number one manufacturing challenge is actually doing your homework, no matter how simple the project or how many times you’ve done it. In the case of the extruded rod, we should have asked the customer if the rods needed a nice cosmetic finish. It turns out they did, and we assumed they didn’t. Ouch!

After you’ve done your upfront homework, the challenge becomes communicating what you’ve learned to your employees and vendors. In the case of our new extruded shape project, we’ve included production planning, extrusion/finishing supervisors, QA Manager, Plant Manager, Sales Manager & GM in the homework stage. They’ve given input on how to create written work instructions for us to follow. We’ll also be inviting two of our vendors to a meeting to explain the project to them so they fully understand what is expected.

Once you’ve done your homework and communicated your findings, the third challenge is execution. If each team member follows instructions, and asks questions if they don’t understand the instructions, we have a very good chance of having a happy customer. During the course of production, unforeseen challenges may arise. Usually, those are much easier to solve than the ones you should have known about if you’d done your homework ahead of time.