The beginning of a new year is a good time to look back & reflect on the previous one. For Profile Precision Extrusions 2017 was eventful:

- Installation of a new extrusion press

- Purchase of a new CNC machining center

- Hiring new team members to join our merry band of miniature aluminum extrusion experts

- Achieving a new record for total yearly shipments

- We also made a few of mistakes which we learned from, and will use to our customers advantage in the future

What a great year! In 2018 we’ll continue to expand the definition of Precision Miniature Aluminum Extrusion.

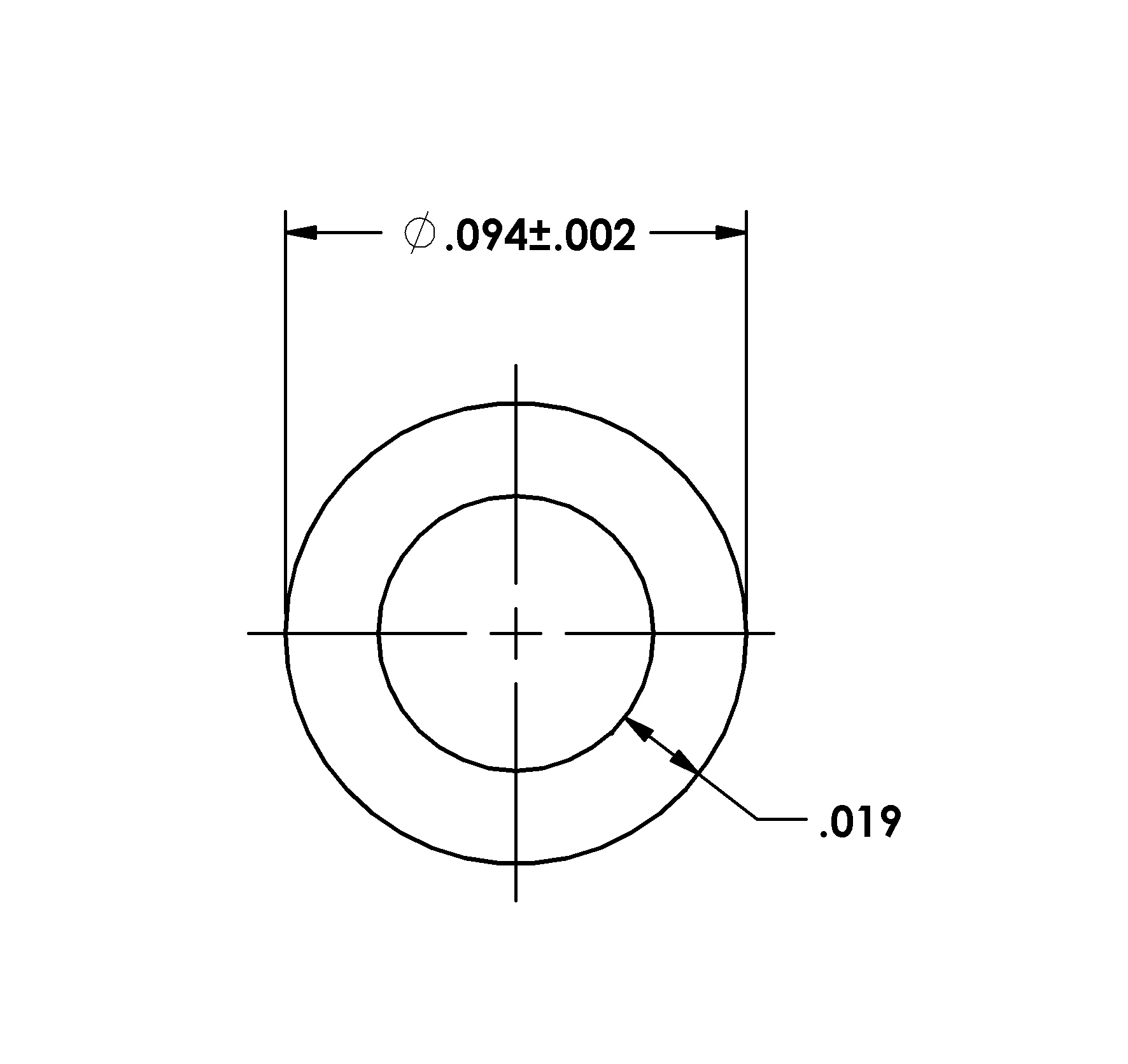

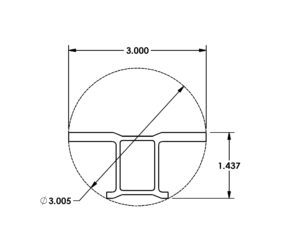

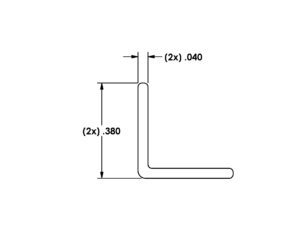

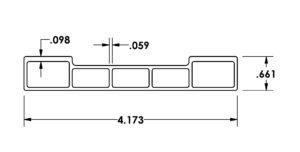

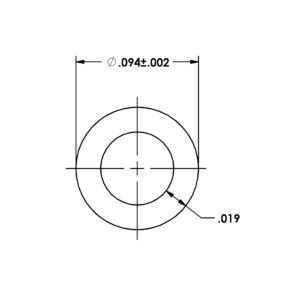

Historically precision miniature extrusions and tubes fit into a 3.5” diameter circle and/or had wall thicknesses from .030 – .050 inches.

Over the past 10 years that definition of precision extrusions has expanded to parts fitting a 5” diameter circle and wall thicknesses less than .030” inches.

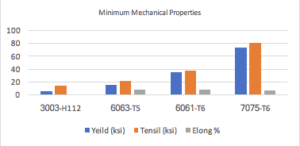

The alloys & tempers that are historically used to produce precision extruded tubing and shapes are 3003-H112, 6063-T5, and 6061-T6. This graph is a comparison of the minimum yield strength of the 3 alloys. (7075-T6, an aerospace alloy, has been added for comparison purposes only)

To find out more about designing miniature extrusions or precision aluminum tubes please visit our Design Tips page or give us a call at 623.936.5599.