As we’ve discussed in previous posts, aluminum shapes and extruded aluminum tube are used extensively in modern aircraft. Aluminum’s weight to strength ratio has been important to aviation reaching all the way back to the Wright Brothers. Profile Precision Extrusions supplies extruded aluminum shapes and tubing for a wide variety of applications, principally within the aircraft interior.

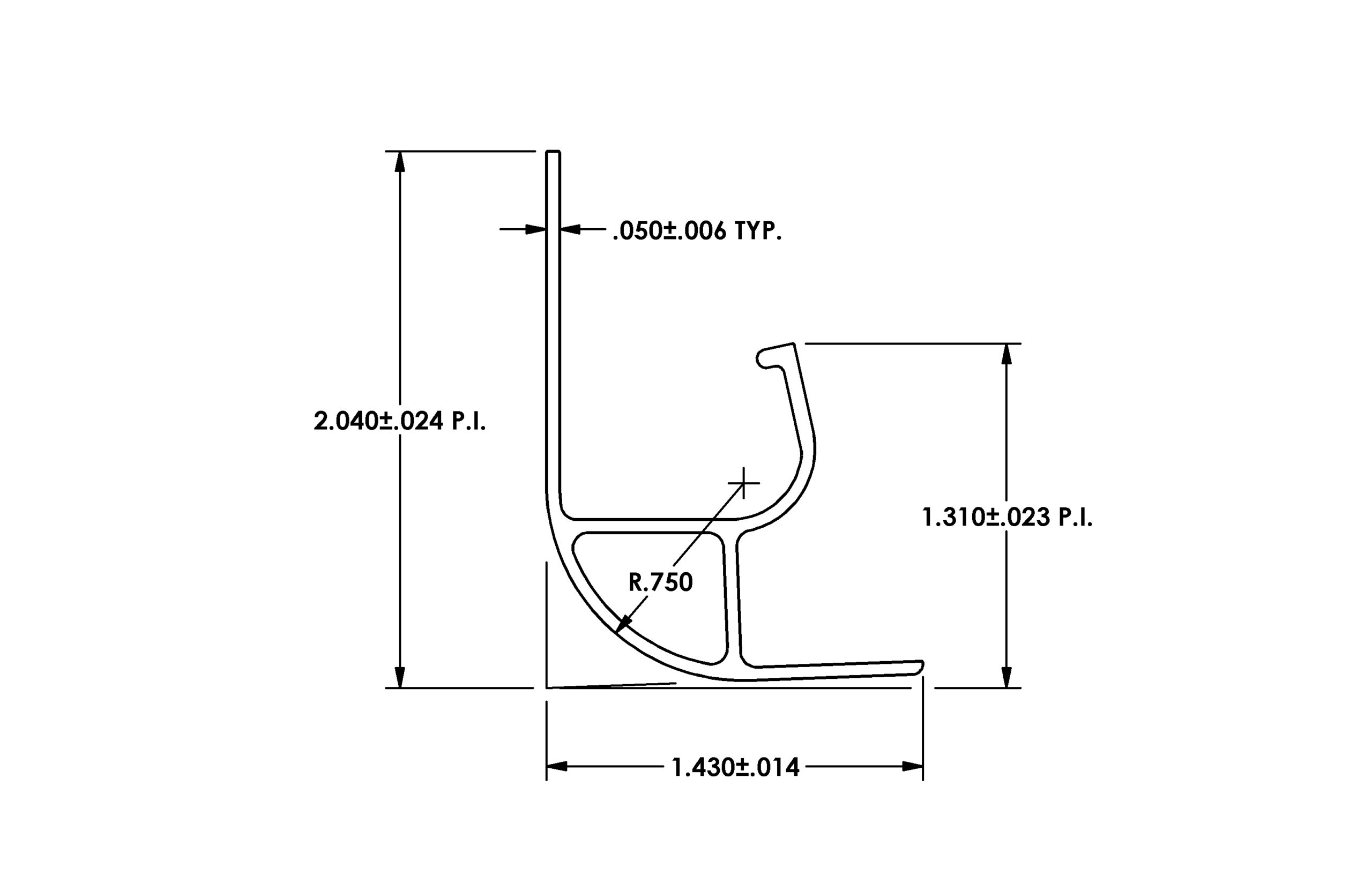

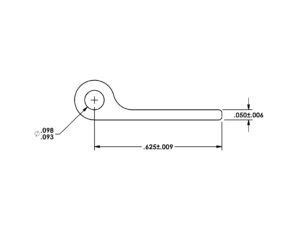

Hinges are found throughout the interior of an airplane on interior doors, overhead bins and galley workstations. The finished hinges are extruded in either solid or hollow designs. Typically, they are extruded using 6061-T6511. This alloy is usually chosen because of its relatively high strength, good machinability and good anodize response. The hinges are machined, anodized, assembled and supplied in lengths from a few inches to over 120”.

Brackets are used to affix interior components to the aircraft frame and interior walls. The brackets that hold overhead bins in place are a good example of the use of extruded aluminum. Like extruded aluminum hinges, brackets are typically made from 6061-T6511. Custom extruded brackets have been designed by aerospace engineers to take advantage of the metals light weight and ability to take complex forms.

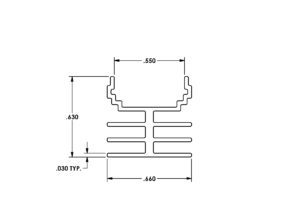

LED’s significantly lowers the power required for interior lighting needs. In addition, they lower maintenance costs due to their long life as compared with other types of lighting. Finally, they offer the ability to customize colors and hues to match the interior color schemes of each airline. Extruded aluminum shapes are used as both a bracket and heat sink. The aluminum extrusion holds the LED circuit board in place. It also cools the circuit board by pulling heat away and dissipating it into the air. 6063-T5 is the most common alloy of choice for LED brackets & heat sinks. The designs for these aluminum extrusions typically call for wall thickness between .025” to .035”. 6063 alloy is easier to extrude than 6061 with wall thicknesses that thin.

Profile Precision extrudes parts for many other aerospace applications. Contact us today with your design challenge, whether the application is aerospace, medical, recreational or industrial. We have over 20 years of experience in successfully bringing designs from prototypes to production.