Profile Precision Extrusions builds hundreds of new dies each year. One of our customers has over one hundred twenty five designs with us. However, many of the new dies we build are prototypes for new customers. With hundreds of extrusion companies in the United States why do many new product development engineers choose to work with Profile Precision Extrusions? In addition to being great guys, PPE offers low cost tooling and free samples, no minimum order size, and components, rather than just extrusions.

Free samples with purchase of a die

Aluminum extrusion dies are very economical compared to tooling for casting or injection molding. Depending on the design, an aluminum extrusion die can cost as little as $500. The dies typically take just a few short weeks to build. PPE always includes free samples with the purchase of an extrusion die. In addition, a first article inspection report (FAR) based upon the AS9100 aerospace standard is supplied with the samples.

No minimum order size

PPE has no minimum order size for aluminum tubing or extruded aluminum shapes. The vast majority of aluminum extrusion companies have a minimum order size of at least five hundred pounds. In fact, many have a two thousand pound minimum! Our philosophy is simple, make only as much as the customer needs. We want to be in on the ground floor of new project development and grow as the project grows. We’re proud to say that many of our largest customers today started out as new product development projects.

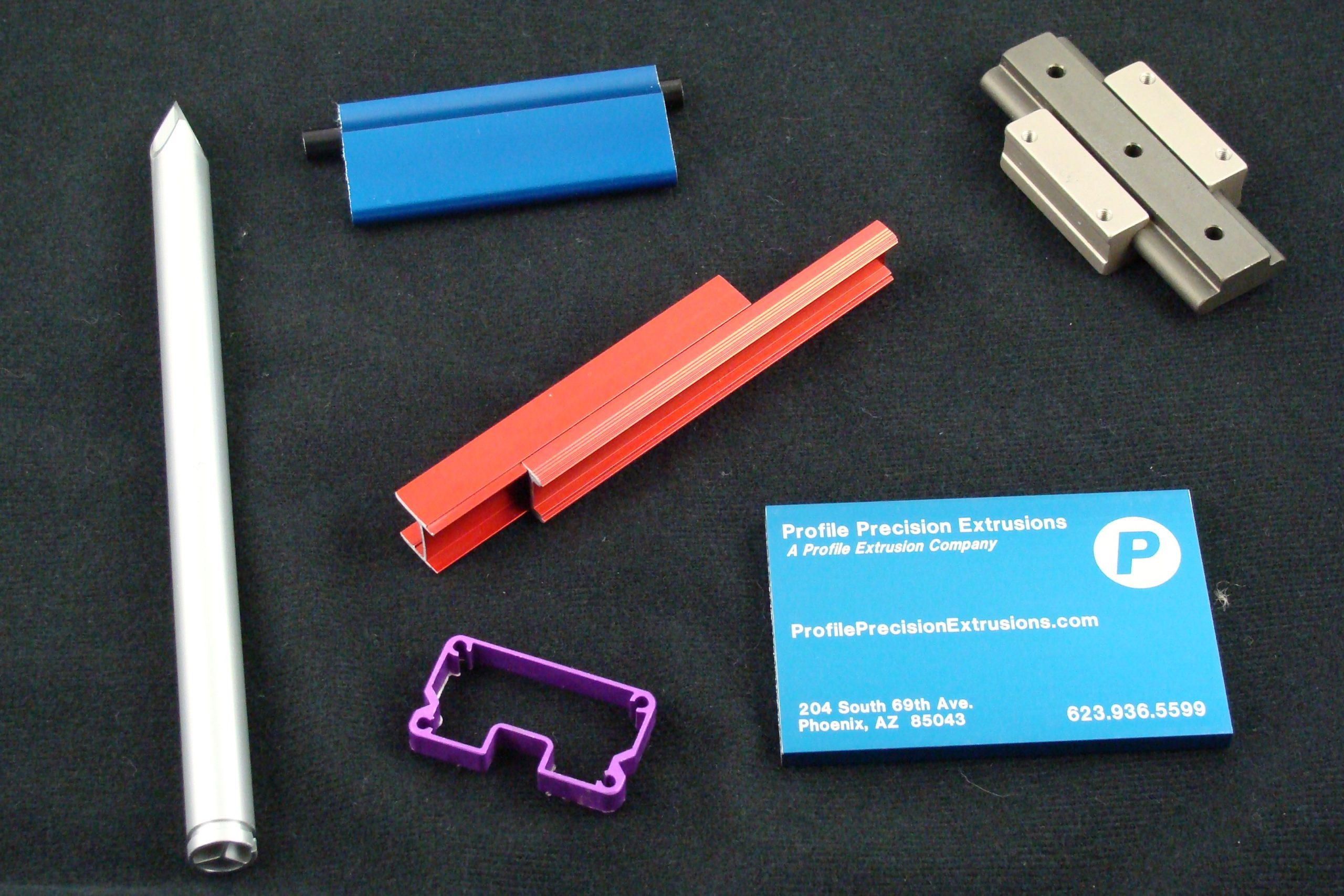

Buy a component, not an extrusion

Extruded aluminum shapes and aluminum tubing are typically not used in long lengths. They are turned into components by cutting to length, machining, punching or coating. Seventy-eight percent of Profile Precision customers choose to have us supply a fabricated component. Having us supply the fabrication services allows our customers to simplify their aluminum supply chain, lower the overall component cost, and reduce the overall production time. Profile Precision Extrusions is classified as an essential business. We continue to produce aluminum extrusions for a wide variety of industries. We are following social distancing guidelines, checking employee temperature when reporting for work, offering PPE to employees, continually cleaning and sanitizing common areas. We hope you and your family are safe and healthy. When you’re ready for your next aluminum extrusion project, we hope to hear from you.

Call us today and find out how we can help you lower your overall costs, increase quality, and save time by allowing us to manage the value chain for you. Profile Precision Extrusions would love to help with your unique challenge!