Industries Served

Aerospace

Profile Precision has supplied extrusions to the aerospace industry for over 25 years. We have been ISO 9001 registered since 2012. Our quality records retention is indefinite, we supply actual chemistry for each order, test for & report actual mechanical properties for each order, and all of our aluminum alloys meet REACH & RoHS requirements.

Commercial aviation customers range from Boeing & Airbus Tier 1 suppliers to distributors and machine shops that support the aircraft supply chain. We produce extrusions used in:

-

- LED interior lights

- Hinges used for galley and overhead bin doors

- Structural extrusions for lavatories

-

- Overhead bin brackets

- Tubes used as pins in honeycomb panels

- Satellite manufacturers rely on us to produce very complicated heat pipe extrusions used to cool the electronics inside the satellite.

Aerospace

Profile Precision has supplied extrusions to the aerospace industry for over 25 years. We have been ISO 9001 registered since 2012. Our quality records retention is indefinite, we supply actual chemistry for each order, test for & report actual mechanical properties for each order, and all of our aluminum alloys meet REACH & RoHS requirements.

Commercial aviation customers range from Boeing & Airbus Tier 1 suppliers to distributors and machine shops that support the aircraft supply chain. We produce extrusions used in:

-

- LED interior lights

- Hinges used for galley and overhead bin doors

- Structural extrusions for lavatories

-

- Overhead bin brackets

- Tubes used as pins in honeycomb panels

- Satellite manufacturers rely on us to produce very complicated heat pipe extrusions used to cool the electronics inside the satellite.

Healthcare

Extruded aluminum tubing and extruded shapes are widely utilized in the medical device industry, with its uses ranging from biomedical research to your doctor’s office to surgical suites. We produce aluminum tubing and extruded shapes for medical devices such as stethoscopes, surgical trocars, optical light tips for spinal surgery, and electroporation cuvettes used in DNA research.

- We offer complete turnkey fabrication services on all custom extrusions along with a wide variety of coating options.

- Profile Precision Extrusions has worked with a number of medical device manufacturers on manufacturing annealed aluminum tubes that are very malleable. The flexibility that our annealed aluminum tubes offer provides an unparalleled advantage for lighting applications during minimally invasive surgeries over traditional stainless tubes, which cannot be bent.

- We offer complete turnkey fabrication services on all custom extrusions along with a wide variety of coating options.

Healthcare

Extruded aluminum tubing and extruded shapes are widely utilized in the medical device industry, with its uses ranging from biomedical research to your doctor’s office to surgical suites. We produce aluminum tubing and extruded shapes for medical devices such as stethoscopes, surgical trocars, optical light tips for spinal surgery, and electroporation cuvettes used in DNA research.

- We offer complete turnkey fabrication services on all custom extrusions along with a wide variety of coating options.

- Profile Precision Extrusions has worked with a number of medical device manufacturers on manufacturing annealed aluminum tubes that are very malleable. The flexibility that our annealed aluminum tubes offer provides an unparalleled advantage for lighting applications during minimally invasive surgeries over traditional stainless tubes, which cannot be bent.

- We offer complete turnkey fabrication services on all custom extrusions along with a wide variety of coating options.

Industrial

Profile produces custom shapes and extruded tubing for many industrial applications. 6061-T6 alloy is specified in many applications requiring moderate strength, good machinability and good anodize response. 6063-T5 is commonly used in applications requiring very thin walls, highly cosmetic finishes, and typically is a little lower in cost than 6061-T6.

- Linear slides designs allow for very precise movement for motion control and robotic applications

- Telescoping tube designs are used for 2-piece drive shafts and camera tripods

- Signage for offices and commercial office space utilize 6063-T5 for its excellent anodize response and thin walls

- LED light extrusions take advantage of the good thermal conductivity of aluminum to keep the LED’s cool and extend their useful life

- Standard hollow and solid shapes are utilized by machine shops in many industries to fabricate prototypes and small production runs

Industrial

Profile produces custom shapes and extruded tubing for many industrial applications. 6061-T6 alloy is specified in many applications requiring moderate strength, good machinability and good anodize response. 6063-T5 is commonly used in applications requiring very thin walls, highly cosmetic finishes, and typically is a little lower in cost than 6061-T6.

- Linear slides designs allow for very precise movement for motion control and robotic applications

- Telescoping tube designs are used for 2-piece drive shafts and camera tripods

- Signage for offices and commercial office space utilize 6063-T5 for its excellent anodize response and thin walls

- LED light extrusions take advantage of the good thermal conductivity of aluminum to keep the LED’s cool and extend their useful life

- Standard hollow and solid shapes are utilized by machine shops in many industries to fabricate prototypes and small production runs

Outdoor/ Recreation

Profile produces custom hollow bike rim extrusions for the bicycle industry. The extrusions are rolled into hoops to form the wheel rim. Profile has worked very closely with its customers to develop a production process that yields very consistent temper and dimensions along the length of the extrusions. The designs have very thin walls, down to .030” or less, to minimize the wheel weight and improve ride comfort.

Profile produces telescopic tubing for the photography and ham radio market. The tubes are thin walled to reduce weight and have very precise diameters so they can telescope into one another easily. Profile also produces larger hollow telescoping tubes for film & TV camera tripods.

Outdoor/ Recreation

Profile produces custom hollow bike rim extrusions for the bicycle industry. The extrusions are rolled into hoops to form the wheel rim. Profile has worked very closely with its customers to develop a production process that yields very consistent temper and dimensions along the length of the extrusions. The designs have very thin walls, down to .030” or less, to minimize the wheel weight and improve ride comfort.

Profile produces telescopic tubing for the photography and ham radio market. The tubes are thin walled to reduce weight and have very precise diameters so they can telescope into one another easily. Profile also produces larger hollow telescoping tubes for film & TV camera tripods.

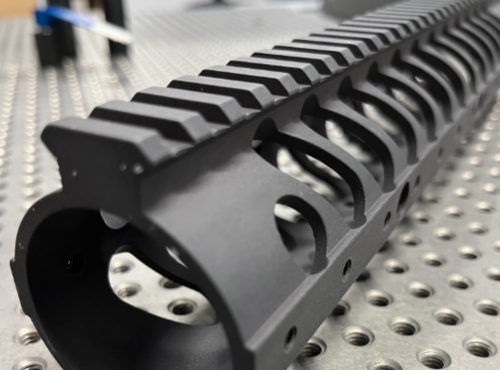

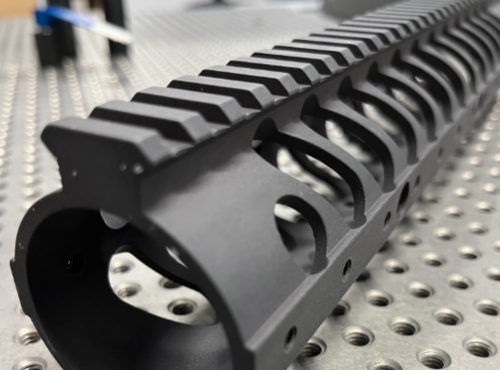

Firearms/ Defense

Profile regularly extrudes aluminum tubes and custom aluminum designs for the firearms industry. Profile is ITAR registered.

- Small diameter tubes are extruded and used to hold primers in reloading machines

- Picatinny rails are extruded and machined from 6061-T6. The rail dimensions can be extruded to print and not machined to specification after extrusion.

- Handguards are regularly produced with and without Picatinny rails incorporated into the design

- Triggers and trigger guards are supplied in 6061-T6

Firearms/ Defense

Profile regularly extrudes aluminum tubes and custom aluminum designs for the firearms industry. Profile is ITAR registered.

- Small diameter tubes are extruded and used to hold primers in reloading machines

- Picatinny rails are extruded and machined from 6061-T6. The rail dimensions can be extruded to print and not machined to specification after extrusion.

- Handguards are regularly produced with and without Picatinny rails incorporated into the design

- Triggers and trigger guards are supplied in 6061-T6

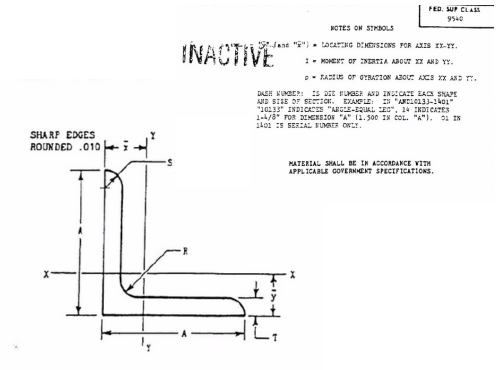

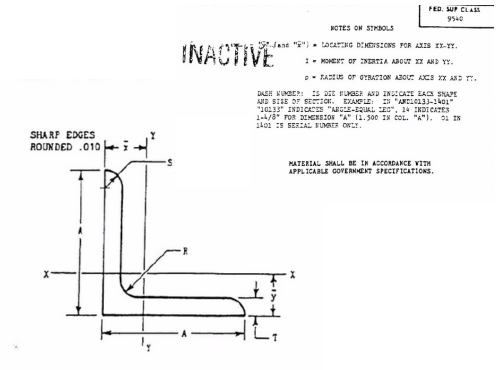

AND Extrusions (Army-Navy Aeronautical Design Standards)

- In the 1940’s the Department of Defense developed a series of structural aluminum extrusion designs. The standardized designs encompass angles, T-shapes, I-beams, and U-channels. The commercial aviation and aerospace industry has adopted the designs. They are regularly produced using 6061-T6511 by Profile.

- AND 10133-xx

- AND 10134-xx

- AND 10135-xx

- AND 10136-xx

- AND 10137-xx

- AND 10138-xx

- AND 10139-xx

- AND 10140-xx

- AND 10141-xx

AND Extrusions (Army-Navy Aeronautical Design Standards)

- In the 1940’s the Department of Defense developed a series of structural aluminum extrusion designs. The standardized designs encompass angles, T-shapes, I-beams, and U-channels. The commercial aviation and aerospace industry has adopted the designs. They are regularly produced using 6061-T6511 by Profile.

- AND 10133-xx

- AND 10134-xx

- AND 10135-xx

- AND 10136-xx

- AND 10137-xx

- AND 10138-xx

- AND 10139-xx

- AND 10140-xx

- AND 10141-xx