Aluminum Extrusion Quick Start Guide

AEROSPACE ALLOYS

2014, 2024, 7075 & 7050 require special processing and heat treating.

We have a limited capability to extrude and process these alloys. If we cannot extrude your design due to our capabilities we will be happy to give you a referral.

CRITICAL DIMENSIONS

Be sure to identify the 1-2 most critical dimensions, and tolerances required.

COSMETIC SURFACES

Be sure to identify the surfaces that are cosmetically important.

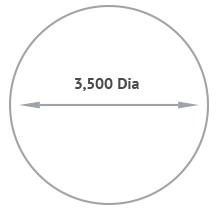

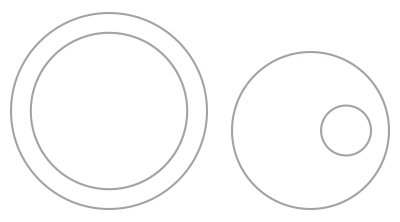

PART SIZE

The parts we manufacture need to fit inside of a 3.50” – 4.00” diameter circle

MINIMUM WALL THICKNESS

| Alloy | Minimum Wall Thickness |

| 3003 | .020” |

| 6063 | .025” |

| 6061 | .030” |

| Alloy | Minimum Wall Thickness |

| 3003 | .020” |

| 6063 | .025” |

| 6061 | .030” |

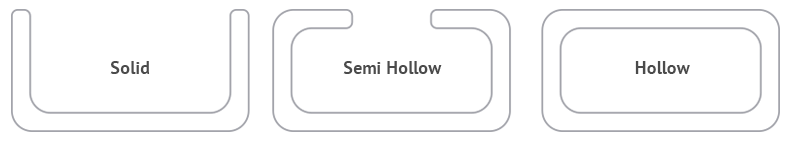

EXTRUSION TYPES

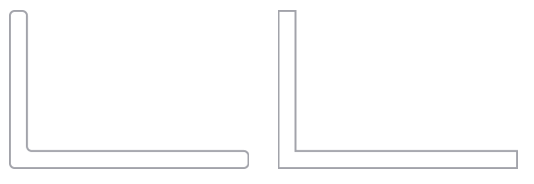

UNIFORM WALL THICKNESS

Uniform wall thicknesses are less costly to extrude

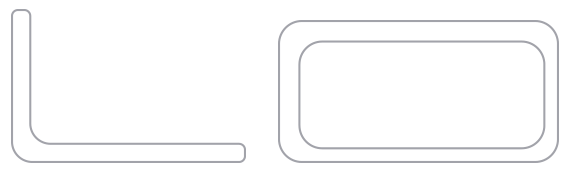

ROUNDED FILLETS & CORNERS

Rounded corners & fillets are easier to extrude than sharp ones.

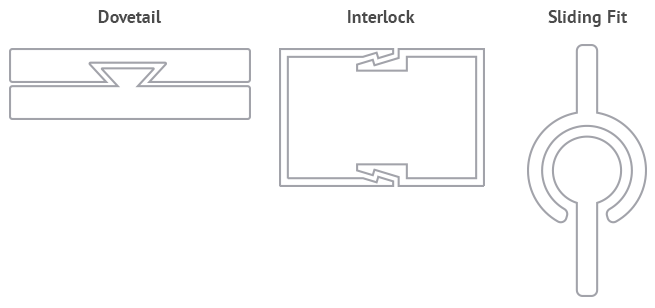

JOINING METHODS

TONGUE RATIO

Easy / 3:1 Ratio

Challenging / 5:1 Ratio

Extremely Difficult / 8:1 Ratio

SYMMETRY

Symmetrical parts are easier to extrude

TOOLING COSTS

| Shapes Type | Average Cost | Lead Time |

| Solid | $750 | 3-4 Weeks |

| Semi Hollow | $1350 | 3-4 Weeks |

| Hollow | $1850 | 4-5 Weeks |

LEAD TIMES

Typical Lead Time for Mill Finish Extrusions: 5-6 weeks (as of November 2022)

| Process | Additional Lead Time |

| Cut-to-Length or Deburr | 2 Weeks |

| Anodize | 3 Weeks |

| Machining | 3-4 Weeks Depending on complexity |

| Process | Additional Lead Time |

| Cut-to-Length or Deburr | 2 Weeks |

| Anodize | 3 Weeks |

| Machining | 3-4 Weeks Depending on complexity |