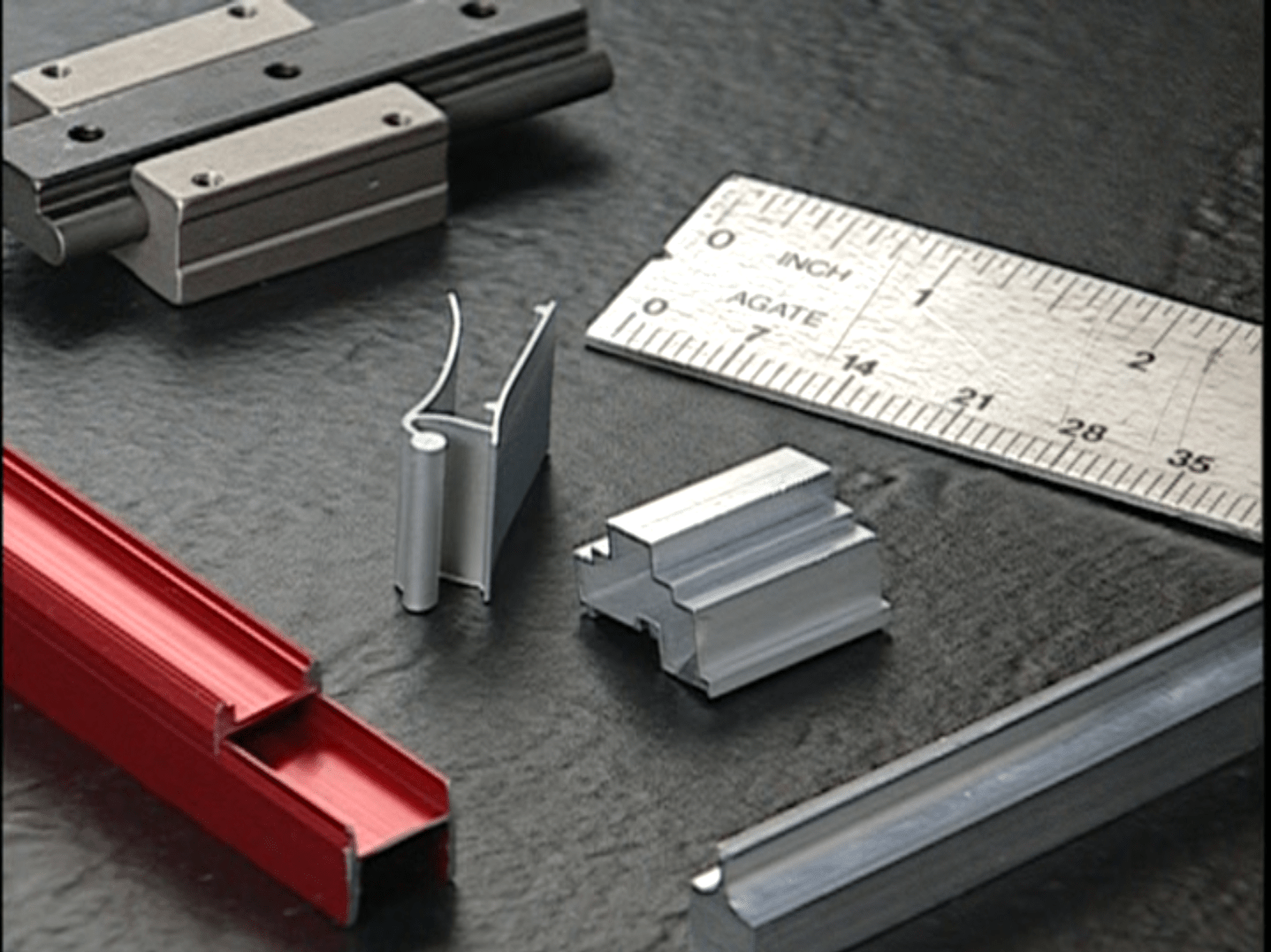

Extruding aluminum is similar to squeezing toothpaste out of a tube. It is a versatile manufacturing process ideal for creating a wide array of designs from simple angles to round tubes, to complex profiles. Understanding if this production method suits your project is key to achieving the desired outcome.

Understanding Aluminum Extrusion

Aluminum extrusion involves heating aluminum billets and pushing them through a die to create continuous profiles. This process’s flexibility makes it perfect for producing everything from basic structural shapes to intricate custom designs.

Design Checklist for Aluminum Extrusion

Design Essentials:

- Start with a basic sketch or a detailed CAD file, specifying your ideal dimensions and tolerances.

- Identify the aluminum alloy and temper. 6061-T6 and 6063-T5 are very common for medical and industrial designs

- Highlight cosmetically important surfaces and specify any coatings like anodize, chem film, or paint.

- Determine the length of the finished extrusion and the desired quantity.

Additional Considerations

- Ask for price breaks based upon the expected growth in volume of your project.

- Consider post-extrusion treatments for aesthetic or functional purposes. (see Finishing Treatments below)

- Define desired dimensional tolerances for key features.

- Consider post-extrusion machining requirements.

- Discuss with the mill lead time expectations for die production, samples, and production volumes.

- Remember, aluminum’s infinite recyclability adds a sustainability edge to your project.

At Profile Precision Extrusions, we excel in new product development. On average we help bring 83 new designs to life each year. We offer free design consultations and we do not have a minimum order size.

Real-World Applications and Misconceptions

Common Misconceptions:

- Extrusion Die Costs: Contrary to belief, most dies are under $2000, far less than injection molding tooling.

- Minimum Order Sizes: We don’t have minimum order requirements, making prototyping and development as inexpensive as possible.

- Industry Tolerances: We routinely achieve tolerances half of what the industry standard permits, ensuring precision in every project.

Optimizing Designs and Finishing Options

Profile Precision Extrusions aids clients in refining their designs for extrusion, ensuring both cost-effectiveness and functionality. Our one-stop-shop approach simplifies project management by offering additional services like cutting, machining, and coating. from a single vendor.

Finishing Treatments:

- Anodize: Ideal for corrosion resistance and aesthetic enhancements.

- Hard Coat Anodize: Offers superior wear resistance.

- Chem Film Coating: Another excellent option for corrosion resistance.

- Powder Coating: Provides both corrosion resistance and a wide range of cosmetic finishes.

These finishes not only protect against corrosion but also contribute to the final product’s aesthetic appeal, tailoring each project to its specific application needs.

Let’s Collaborate

Ready to explore aluminum extrusion for your next project? With Profile Precision Extrusions, you gain a partner dedicated to bringing your innovative ideas to life. Contact us today to start the conversation and leverage our expertise for your project’s success. Contact us on our website or give us a call at (623) 936-5599 to discuss your next project.