When it comes to enhancing the properties of aluminum extrusions, anodizing stands out as a versatile and effective method. Profile Precision Extrusions (PPE) offers two primary types of anodizing: Type II Sulfuric Anodizing and Type III Hard Coat Anodizing, each with its unique benefits and applications.

Understanding Type II Sulfuric Anodizing

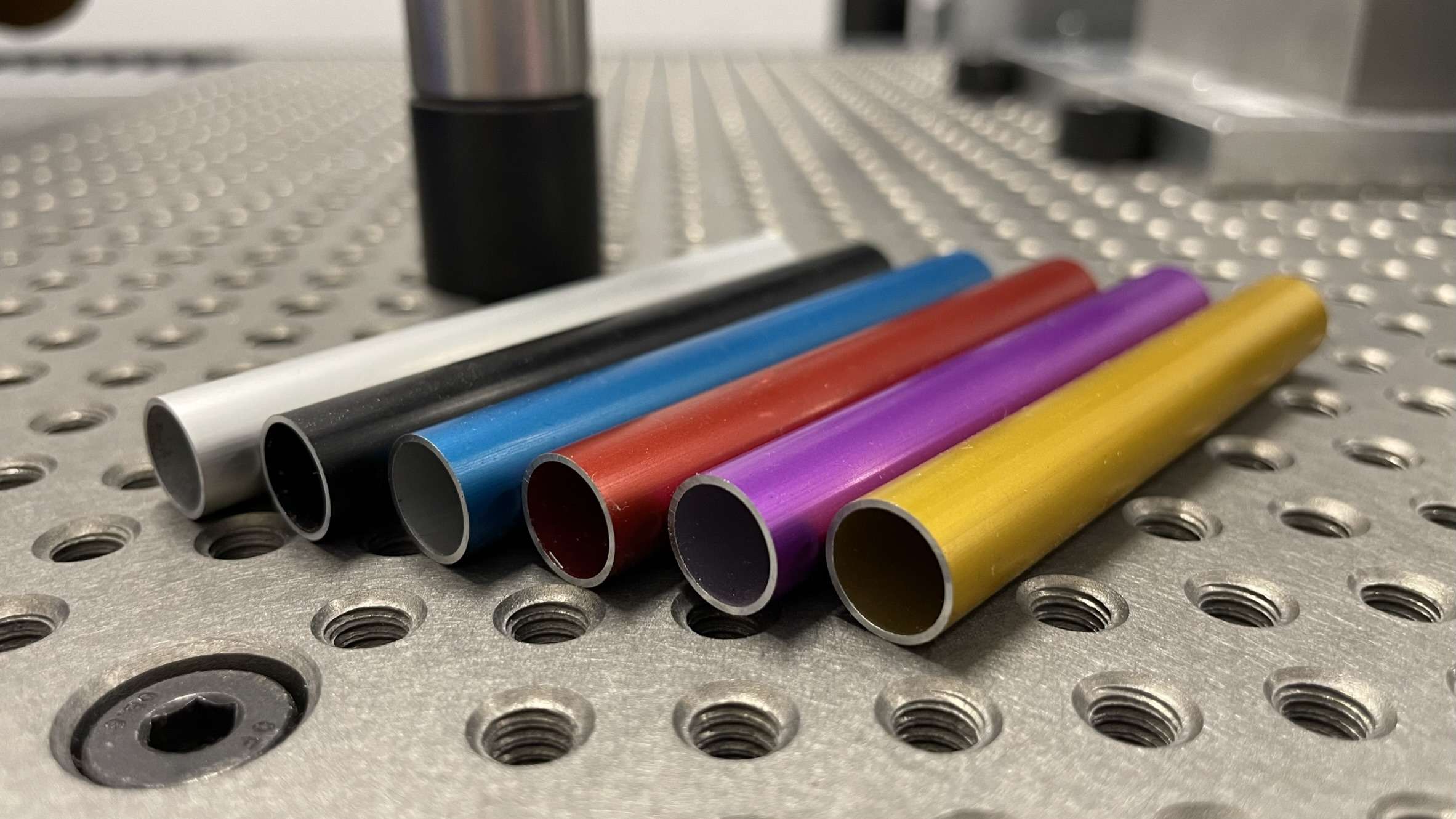

Type II Sulfuric Anodizing, compliant with Mil-A-8625 standards, offers a versatile solution for enhancing aluminum extrusions. With its ability to provide improved appearance, scratch resistance, and a wide range of color options, Type II anodizing is well-suited for various applications.

Benefits and Applications of Type III Hard Coat Anodizing

Type III Hard Coat Anodizing, also conforming to Mil-A-8625 standards, provides unparalleled durability and abrasion resistance. This type of anodizing is particularly favored for projects requiring extreme durability and surface hardness, such as heavy-duty industrial settings.

Chem Film Coatings: Enhancing Protection and Primer

In addition to anodizing, Profile Precision Extrusions (PPE) offers Chem film coatings per MIL-DTL-5541 standards. Chem film serves as an excellent primer for painting aluminum and prevents oxidation, offering both Type I and Type II options.

Quality Assurance in Anodizing Processes

PPE prioritizes quality and consistency throughout the anodizing process, especially for complex or custom extrusion profiles. By partnering with certified vendors and conducting thorough inspections, PPE ensures that each anodize order meets the specified requirements.

Common Industries Utilizing Anodized Aluminum

Anodized aluminum finds applications across various industries, including aerospace, medical devices, and industrial machine guarding. Type II anodizing, in particular, is commonly used for its corrosion resistance and surface protection properties.

Sustainability and Environmental Compliance

Both Type II and Type III anodizing, along with Chem film coatings using trivalent chromate, comply with RoHS regulations, contributing to sustainability and environmental standards while providing superior performance and protection.

Choosing the Right Anodizing Solution

When assisting clients in choosing between Type II and Type III anodizing, PPE considers factors such as required durability, aesthetic preferences, and environmental considerations. Close collaboration with clients and coating vendors ensures the identification of the optimal coating solution for each unique application.

In conclusion, the choice between Type II and Type III anodizing depends on specific project requirements. With PPE’s expertise and commitment to quality, clients can trust in the effectiveness and reliability of their chosen aluminum coating solution.

Let’s create something extraordinary together. Contact us on our website or give us a call at (623) 936-5599 to discuss your next project.