Aluminum extrusion technology continues to advance, offering new opportunities for innovation and efficiency in manufacturing. The recent Aluminum Extrusion Technology Seminar & Exposition, hosted by the Aluminum Extruders Council, showcased several emerging trends and technological advancements that are reshaping the industry. Profile Precision Extrusions (PPE), an industry leader in custom miniature aluminum extrusions, is at the forefront of adopting and implementing these innovations.

Key Takeaways from the Aluminum Extrusion Technology Seminar & Exposition

The seminar highlighted significant advancements in aluminum extrusion production, including:

-

Reducing Carbon Emissions

The aluminum industry is making significant strides in reducing carbon emissions across the entire value stream, from mining bauxite to recycling aluminum scrap. This initiative is crucial for promoting sustainability and reducing the environmental impact of aluminum production.

-

Rapid Extrusion Profile Inspection

Advances in rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning are being developed. This technology has the potential to eliminate time-consuming sample preparation and can be performed directly at the extrusion press, enhancing efficiency and accuracy in quality control.

-

Rapid Quench Systems

New rapid quench systems, utilizing multiple nozzles and adjustable flow valves, are being developed to cool extrusions uniformly as they exit the press. These systems ensure more consistent tempering along the length of the extrusion, reducing straightness and twist deformations, and improving overall product quality.

-

Higher Strength Aluminum Alloys

Higher strength 6000 series aluminum alloys are being developed, particularly for automotive applications where strength and durability are paramount.

-

Artificial Intelligence Integration

Artificial intelligence is being incorporated into various aspects of the extrusion process, including predictive maintenance, die design, and die correction processes. AI and machine learning are being used to optimize plant operations, from quoting to process development for extrusion.

Incorporating cutting-edge technologies at Profile Precision Extrusions has always been at the forefront of enhancing our aluminum extrusion production and fabrication processes. Over a decade ago, we integrated advanced extrusion die technology for automotive microchannel cooling applications into our small tube and hollow shape production. These dies, featuring powder metal substrates coated with chemical vapor deposition (CVD), offer higher productivity, reduced dimensional variation, and extended die life.

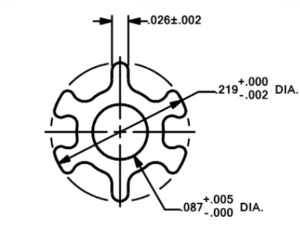

One notable early success was the production of an extruded component used in a surgical device for rotator cuff repair. The device was designed by a division of Smith & Nephew, using 6061-T6 alloy. Our initial attempts with conventional dies failed due to flow issues resulting from the design and alloy choice. The CVD-coated die allowed us to successfully extrude the design and achieve precise tolerances, even after hard coat anodizing.

Our commitment to innovation continues. Since 2017, we have installed a new 4.5” Presezzi extrusion press, acquired a Hexagon coordinate measurement machine (CMM), and added a Micro-Vu vision measurement system. Additionally, we have invested in new machining centers and Mastercam software to support our customers who prefer fabricated components over mill-finish extrusions.

Profile Precision Extrusions seeks out the most challenging projects and designs, leading to new knowledge and technologies that benefit all our customers. Let’s create something extraordinary together. Contact us on our website or call us at (623) 936-5599 to discuss your aluminum extrusion project.