Revolutionizing Product Development with Miniature Aluminum Profiles and Thin Wall Extruded Tubing

Are you an engineer grappling with seemingly impossible aluminum design requirements? You’re not alone. Across industries, from aerospace, industrial, outdoor and recreation, to medical devices in healthcare, the demand for components that are simultaneously lightweight, strong, and precisely shaped has never been higher. Traditional manufacturing methods often fall short when it comes to custom aluminum extrusions, leading to compromises in design or functionality that can derail innovative projects.

Enter precision custom aluminum extrusions – a game-changing solution that’s transforming product development across sectors. At Profile Precision Extrusions, we specialize in turning “impossible” aluminum designs into reality, pushing the boundaries of what’s achievable with custom extrusion techniques. Our expertise in creating miniature aluminum profiles and thin wall extruded tubing opens up new possibilities for engineers facing complex design challenges. From redesigning surgical devices to reduce costs and lead times by 50%, to producing heat pipe extrusions for satellites designed to operate in space for over 15 years, our precision extrusion capabilities help you overcome limitations and bring your most ambitious designs to life.

The Power of Precision: Beyond Standard Extrusions

Standard extrusions have their place, but when it comes to complex, miniature, or highly specific designs, precision custom extrusions shine. Our capabilities allow for:

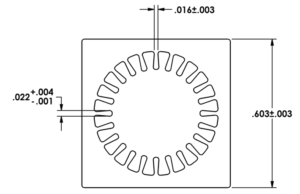

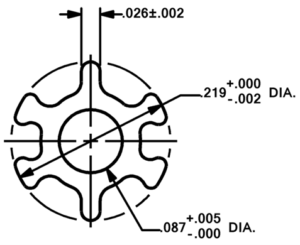

- Wall thicknesses as thin as 0.010″ for R&D projects

- Tolerances as tight as ±0.001″ on certain dimensions

- Complex internal geometries and multi-hollow shapes

These precision capabilities open up new possibilities for engineers in aerospace, medical devices, electronics, and more. As products continue to shrink, we’re seeing increased demand for smaller, thinner, and lighter components, pushing our machining capabilities to new levels of precision.

Aluminum vs. Traditional Materials: A Game-Changing Comparison

Why choose aluminum over materials like stainless steel or titanium? The benefits are compelling:

- Weight Reduction: Aluminum’s high strength-to-weight ratio is crucial for aerospace and automotive applications.

- Cost-Effectiveness: Lower material costs and reduced machining time translate to significant savings.

- Design Flexibility: Complex shapes that would be prohibitively expensive to machine from solid stock become feasible with extrusion.

- Corrosion Resistance: Natural oxide formation provides inherent protection, or specify chem film or anodize coating for even better performance or cosmetic appearance.

Real-World Applications: Solving Industry Challenges

Aerospace: Pushing the Envelope of Performance

In the aerospace industry, every gram matters. Our precision extrusions have been used to create:

- Lightweight structural components for aircraft interiors

- Heat sink profiles for avionics cooling

- Custom-shaped conduits for hydraulic and electrical systems

Medical Devices: Precision Where It Counts

The healthcare industry demands utmost precision and biocompatibility. Our extrusions find applications in:

- Minimally invasive surgical instruments such as trocars, circular staplers, and laparoscopic scissors

- Stethoscopes

- Electroporation cuvettes

The Profile Precision Extrusions Advantage

What sets us apart in the world of custom aluminum extrusions?

- No Minimum Order Size: Perfect for prototyping and small production runs.

- Rapid Turnaround: Typical lead times of 6 weeks for mill finish, 9 weeks for anodized finish.

- Comprehensive Capabilities: From extrusion to CNC machining to finishing, we offer end-to-end solutions.

- Expert Consultation: Our engineering team collaborates with you to optimize designs for extrusion.

Turning Impossible into Reality

In the world of engineering, “impossible” is often just a challenge waiting to be overcome. With precision custom aluminum extrusions, those challenges become opportunities for innovation. Whether you’re designing the next breakthrough in aerospace technology or revolutionizing medical devices, Profile Precision Extrusions is ready to turn your complex designs into reality.

Ready to push the boundaries of what’s possible with aluminum? Contact our team of experts today, and let’s engineer the impossible together. Visit our website or call us at (623) 936-5599 to discuss your custom aluminum extrusion needs and discover how we can bring your innovative designs to life.