As 2024 comes to a close, Profile Precision Extrusions (PPE) reflects on a year of innovation, overcoming complex challenges, and delivering exceptional quality in aluminum extrusion technology. Here’s a look at the milestones that shaped our success.

Achieving the Impossible

In 2024, PPE took on some of the most demanding extrusion projects in the industry, working with both soft and hard aluminum alloys. These “impossible” projects were not just about delivering results but about pushing the boundaries of what’s possible, setting new benchmarks for precision and performance. These projects expanded our knowledge base, allowing us to better serve both current and future clients. Embracing such challenges reinforces our commitment to continuous improvement and innovation, strengthening our reputation as a leader in precision extrusions.

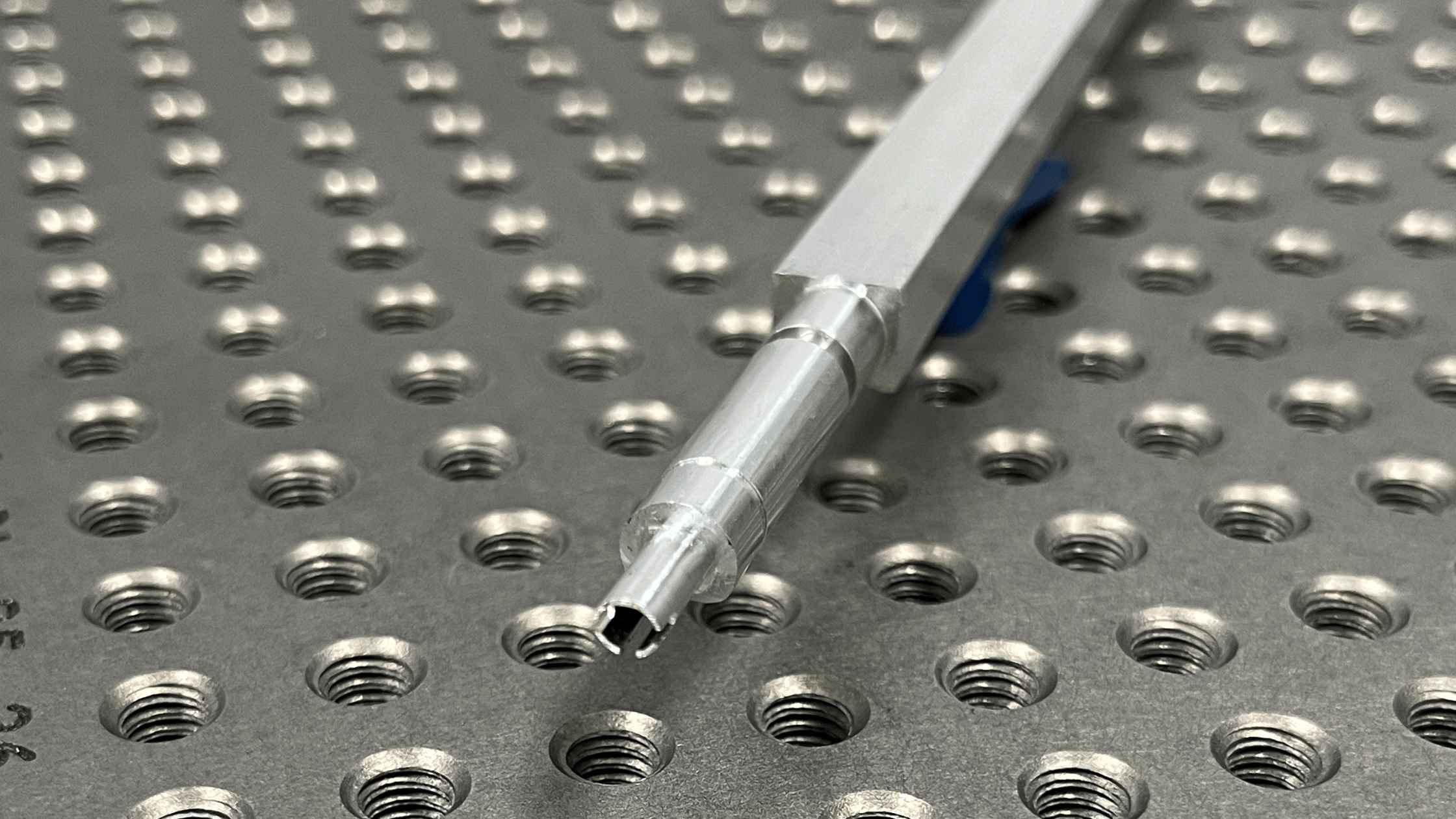

A Notable Success: Medical Device Project

A major highlight this year was our collaboration with Kimball Electronics on a project for Stryker Medical. Over nearly two years, PPE partnered with teams in Europe and the U.S. to develop a highly specialized aluminum extrusion. From defining precise dimensions and tolerances to ensuring compliance with REACH and RoHS standards, we overcame significant obstacles, including redesigning a hollow component to enable the machining of a .016-inch-thick oval feature with our swiss CNC lathe. This project showcases our technical expertise and our ability to work seamlessly across global teams, ultimately delivering a solution that could transform medical device manufacturing.

Adapting to Industry Trends

In response to the growing demand for shorter lead times, PPE introduced expedited order options and began preproducing raw extrusions for machining for key customers. In select cases, we also stocked limited quantities of finished extrusions, improving delivery speed without compromising quality. These proactive measures reflect our understanding of the market’s evolving needs and our commitment to meeting client expectations in an increasingly fast-paced industry. By adapting to these trends, PPE continues to strengthen its position as a trusted partner for clients across multiple sectors.

Investing in Efficiency and Quality

To support our clients’ evolving needs, PPE made strategic investments in equipment and infrastructure in 2024. New acquisitions include:

- A double-end deburring machine

- An automated parts cleaning system

- A screen printer

- A CNC lathe

- A company truck to streamline vendor deliveries

These upgrades have enhanced operational efficiency and our ability to tackle even more complex projects with precision. Each investment represents a commitment to maintaining the highest quality standards while increasing capacity. The new equipment also enables us to provide tailored solutions for a diverse range of industries, from aerospace to healthcare.

Strengthening Client Relationships

Throughout the year, PPE focused on building strong, collaborative relationships with clients. Our personalized approach to problem-solving and dedication to exceeding expectations has fostered trust and loyalty. Whether working on large-scale projects or addressing unique design challenges, we are committed to delivering results that go above and beyond. This client-first philosophy has been instrumental in our continued growth.

Looking Forward to 2025

As we move into 2025, PPE remains committed to innovation, investment, and taking on challenges that others deem impossible. With our focus on continuous improvement, we aim to expand our capabilities, explore emerging technologies in aluminum extrusion, and deepen our impact across industries. We’re excited to develop new opportunities and build on our successes.

To our clients, partners, and team members: thank you for an incredible year. We look forward to achieving even greater milestones together in 2025.

Looking for precision extrusion solutions tailored to your unique needs? Connect with us today to discuss your next project. Contact us to start the conversation!