More often than not, aluminum isn’t the first metal that comes to mind when a medical device engineer is working on a new project. Metals like stainless steel and titanium are used extensively for implants and surgical instruments. Surprisingly, aluminum extrusions have been used extensively by the medical community for many well-known instruments. The ear tubes (binaural) of a stethoscope, the most well-known medical instrument, are made from extruded aluminum tubes. Medical device engineers are considering extruded aluminum shapes and aluminum tubing more often than in the past to solve unique challenges. This is especially true for one use surgical instruments where recyclability, flexible geometry, ease of machining/fabrication, and biocompatible coatings are important.

Flexibility In Medical Device Designs

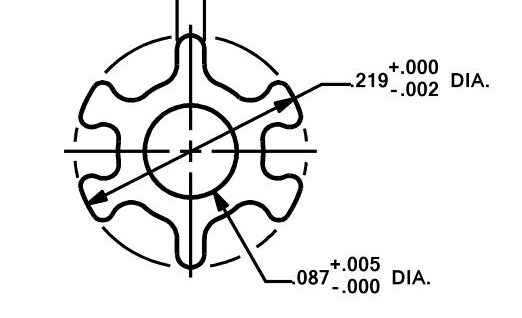

Some Trocar designs developed in the 1990’s utilized the geometric flexibility aluminum extrusions. The hollow designs made it possible to have three very sharp edges for cutting skin and the abdominal wall. The extrusions are fabricated on a Swiss CNC lathe and anodized to prevent oxidation. The outside diameter ranged from 5mm to 12mm which utilized a different extrusion die for each size.

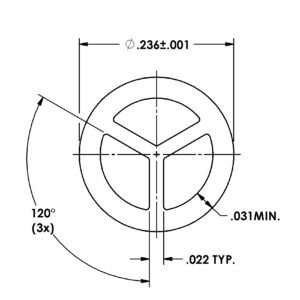

Engineers working on a medical device for rotator cuff repair needed an aluminum extrusion to replace a stainless steel component that was too costly. Utilizing a very small aluminum extrusion shown below was the answer. Both ends are machined on a Swiss CNC lathe, and the machined component is hard-coated anodized prior to shipping to the OEM for final assembly. It replaced a much more expensive stainless steel component that was fabricated using a wire EDM.

Device engineers have taken advantage of annealed aluminum (0 temper) in their design to allow a device to be bent during use. One example is a light tip which is part of a system that illuminates the spine during surgery. A second example is an aluminum tube that is part of a device that replaces heart valves. The parts below are extruded, tempered and fabricated. Both parts are then annealed which makes the aluminum pliable. During surgery they can be bent and placed exactly where the surgeon needs them.

Aluminum extruded shapes and extruded aluminum tubing are also used in veterinary medicine. Profile Precision Extrusions is working on a project to produce .020” wall tubes which will be used as a syringe for cattle and wildlife. Contact us today and find out how we can assist you with your medical design challenge. Free samples are always included with the purchase of an extrusion die.