Profile Precision Extrusions has produced thousands of custom shapes for customers in the past 20 years. Our customers range in size from the sole entrepreneur to large corporations, serving hundreds of industries. The firearms accessories market has been a regular customer of PPE for over 10 years. In 2010 Sturm, Ruger & Co approached Profile Precision to improve the dimensional tolerances of the rail extrusions they had been purchasing from a commercial extruder. PPE was successful in providing an extrusion to meet Ruger’s requirements. Since then, we have produced many precision miniature extrusions and extruded aluminum hollow shapes for the firearms industry including Picatinny Rails, AR Handguards, Scope Mounts, and Primer Tubes and triggers.

Picatinny Rails History & Use

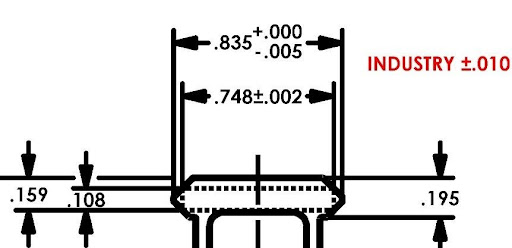

Picatinny rails were developed by the U.S. military in the early 1990s at the Picatinny Arsenal in New Jersey. They desired a mounting rail system that could be standardized, easily produced, and easily inspected. The challenge from an aluminum extrusion standpoint is the Picatinny rail tolerances are much tighter than standard Aluminum Association tolerances. Meeting the dimensional requirements takes attention to detail and a manufacturing process designed for tolerances much tighter than industry norms.

Once the military had finished its design, both civilian and military engineers began to incorporate the design into accessories such as telescopic scope mounts, handguards, tactical lighting, bipods, and slings.

Handguards were an obvious choice to incorporate Picatinny rails into their design. Handguards enclose the barrel of a firearm and protect the user from the hot barrel during use. Mounting accessories like telescopic sights on the top, tactical lighting on either side and slings on the bottom, now became much easier. The extrusions became more challenging because now there were four rails with tight tolerances rather than just one.

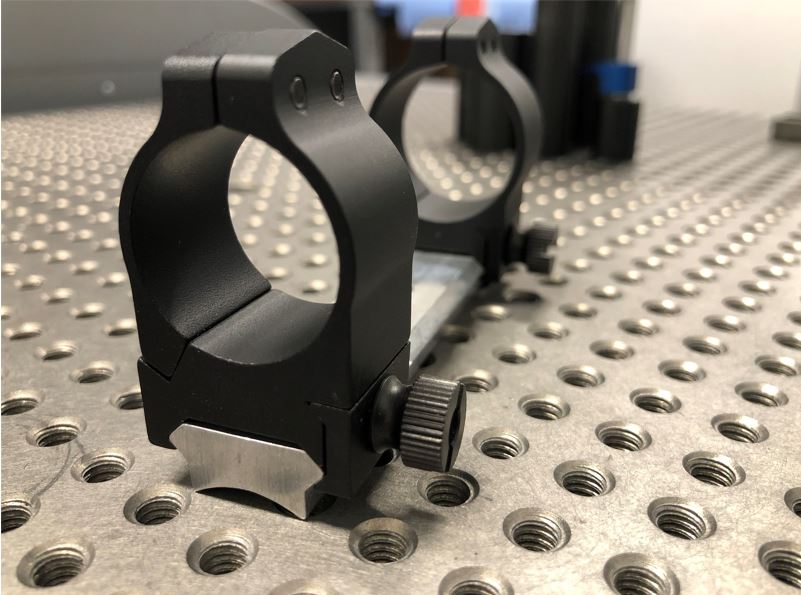

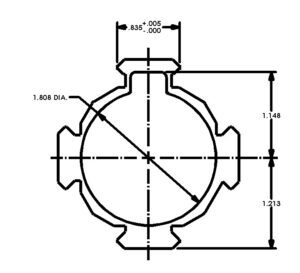

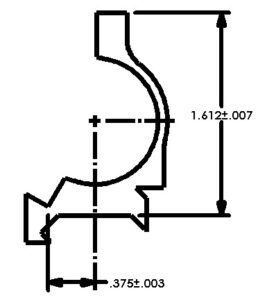

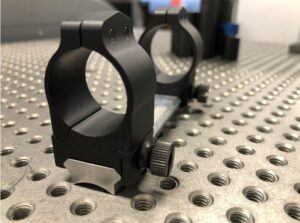

Scope mounts and other accessories are needed to incorporate the Picatinny rail design as well. Ring scope mounts typically utilize a 2-piece design that goes around the body of the scope and clamps on the rail. Below are examples of the ring design that incorporates the Picatinny rail concept, and a photograph of the two pieces mated together.

Scope Ring

In addition to Picatinny rails and handguards, Profile Precision Extrusion makes extruded primer tubes used to reload ammunition and extruded solid designs that are machined into adjustable stock buffer tubes. Contact us today to find out how miniature aluminum extrusion technology can improve your firearms accessory manufacturing.