Aluminum Extrusion Tongue Ratio: How It Impacts Design Feasibility and Manufacturability

Aluminum extrusions provide engineers and designers with a versatile and efficient way to create complex profiles for various industries, from aerospace to medical devices. However, one critical factor that influences an extrusion’s manufacturability is the tongue ratio. Understanding this ratio and its impact can help you optimize your designs for production efficiency and cost-effectiveness.

What Is the Aluminum Extrusion Tongue Ratio?

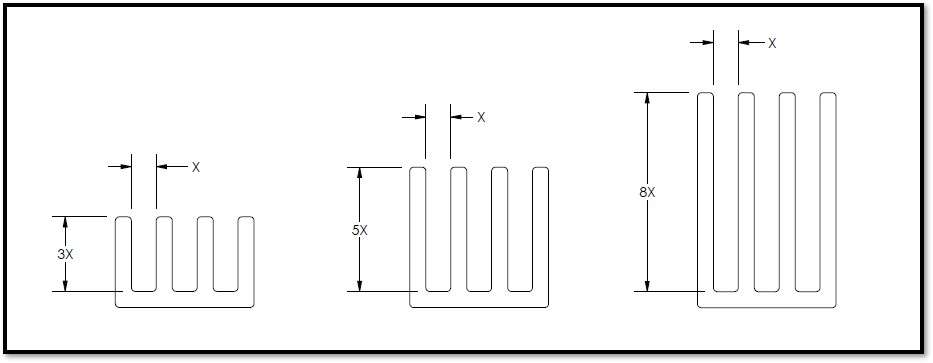

The tongue ratio is a key design consideration in aluminum extrusion, defined as the ratio of the depth of a protruding feature (the “tongue”) to its width. Mathematically, it’s expressed as:

Tongue Ratio = Depth of Feature / Width of Feature

A higher tongue ratio means a deeper, narrower feature, whereas a lower ratio indicates a shallower, wider feature.

Why Does the Tongue Ratio Matter?

The tongue ratio directly affects the complexity of the extrusion die and the success of the extrusion process. Here’s how:

1. Die Strength and Longevity

High tongue ratios place significant stress on the extrusion die. Thin, deep features are more prone to breakage during the extrusion process, reducing die longevity and increasing production costs. Lower tongue ratios create more durable dies and improve operational efficiency.

2. Material Flow and Extrusion Quality

Aluminum must flow evenly through the die to form a uniform profile. When a feature has a high tongue ratio, the metal flow can become uneven, leading to defects like warping or inconsistent wall thickness. Optimizing the tongue ratio helps maintain a stable material flow, reducing defects and improving product quality.

3. Manufacturability and Cost

Designs with extremely high tongue ratios may require additional processing steps, such as post-extrusion machining or secondary operations, to achieve the desired shape. By optimizing the tongue ratio, designers can reduce the need for costly secondary machining and streamline production.

Best Practices for Optimizing the Tongue Ratio

To ensure your extrusion design is both manufacturable and cost-effective, consider these guidelines:

- Keep the tongue ratio below 3:1 whenever possible. While different alloys and die designs allow for some flexibility, staying under this threshold improves manufacturability.

- Use gradual transitions. Avoid abrupt changes in profile depth to encourage smooth material flow.

- Consult with Profile Precision Extrusions. Experienced extrusion engineers can help refine designs to balance feasibility with functionality.

- Consider alternative design solutions. If a high tongue ratio is necessary, evaluate whether post-extrusion machining or assembly techniques might offer a more practical solution.

Final Thoughts

The aluminum extrusion tongue ratio is a crucial factor in determining the feasibility, cost, and quality of your final product. By understanding how it impacts die strength, material flow, and manufacturability, engineers and designers can make informed decisions that lead to more efficient production processes and higher-quality extrusions.

If you’re designing an aluminum extrusion and need expert guidance, Profile Precision Extrusions can help. Our team specializes in complex, precision extrusions to meet your exact specifications. Contact us today to discuss your project!