Profile Precision Extrusions reviews hundreds of extrusion design ideas each month. The designs come from a wide variety of potential customers, from entrepreneurs working at home to engineers…

5 Initial Questions to Ask Your Aluminum Extruder

When choosing an aluminum extrusion provider, what types of questions should you be asking? We recommend initially starting with these 5 questions when searching for your ideal aluminum extruder:…

Who Uses Profile Precision Extrusions

As we’ve discussed in previous posts, aluminum shapes and extruded aluminum tube are used extensively in modern aircraft. Aluminum’s weight to strength ratio has been important to aviation reaching all…

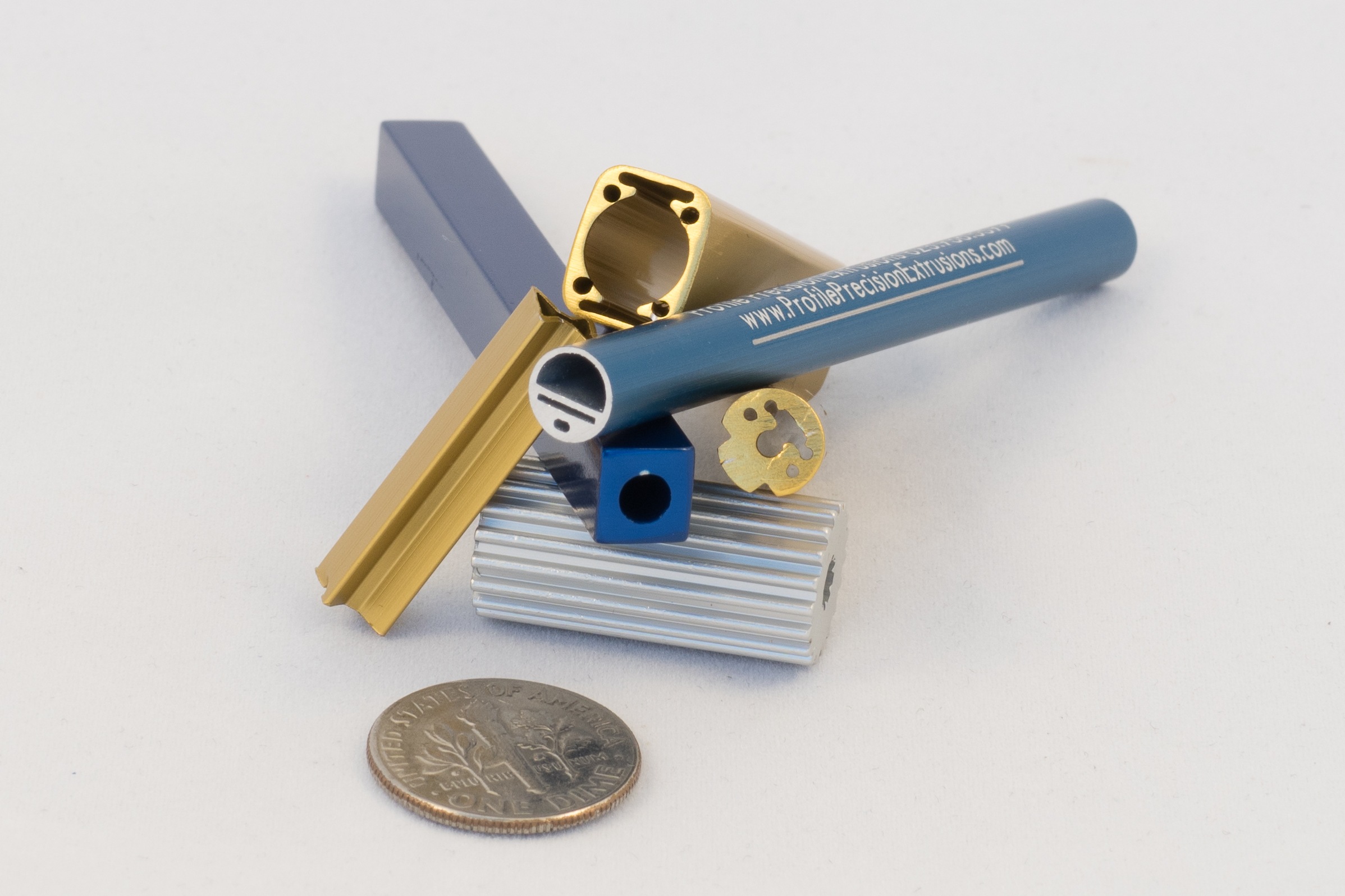

Looking Back on Precision Miniature Aluminum Extrusion

The beginning of a new year is a good time to look back & reflect on the previous one. For Profile Precision Extrusions 2017 was eventful: Installation of a new…

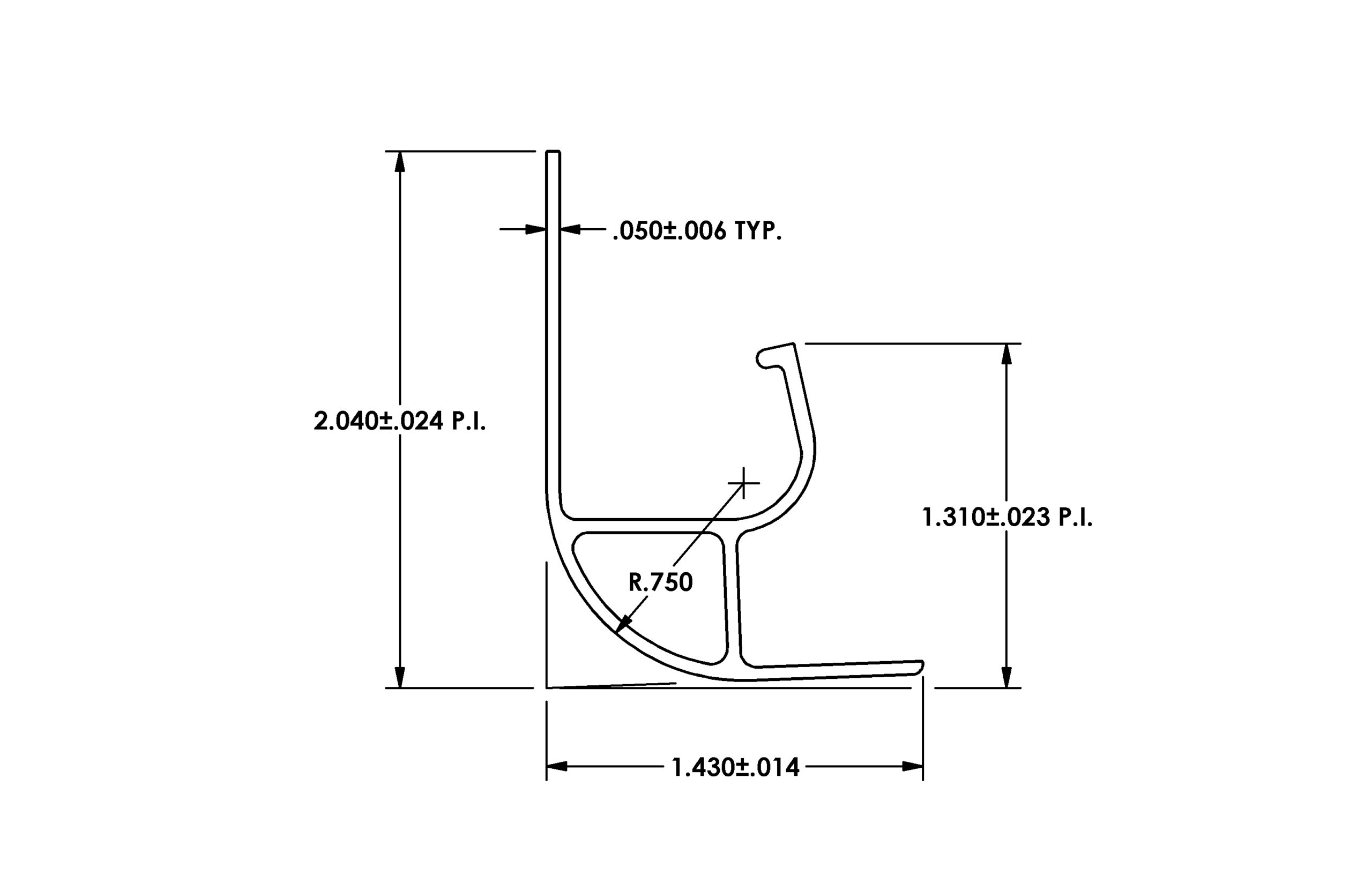

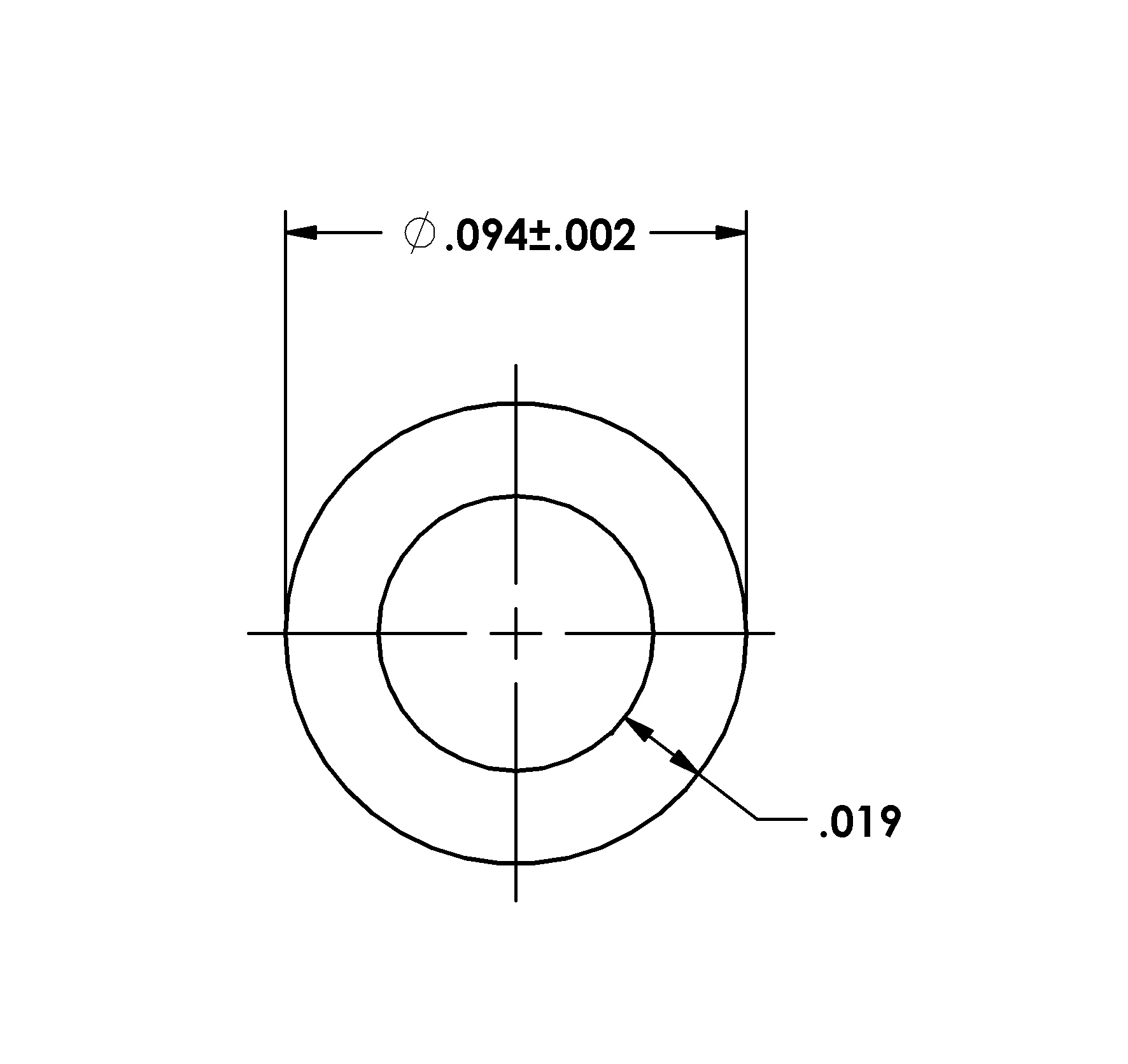

Looking at Things Differently with PPE

At Profile Precision Extrusions, we look at things a bit differently than the rest of our industry. We value ourselves in taking on projects that others shy away from…