Every day at Profile Precision Extrusions, we review new aluminum tube and shape designs. Early on in our discussions with designers, we are asked about our minimum order size policy. Most…

Biomimetics As a Tool For New Development

The great explorer of the truth, the master-builder of human happiness seds one rejects, dislikes, avoids pleasure itself, because it is pleasure, seds but because those who do not know…

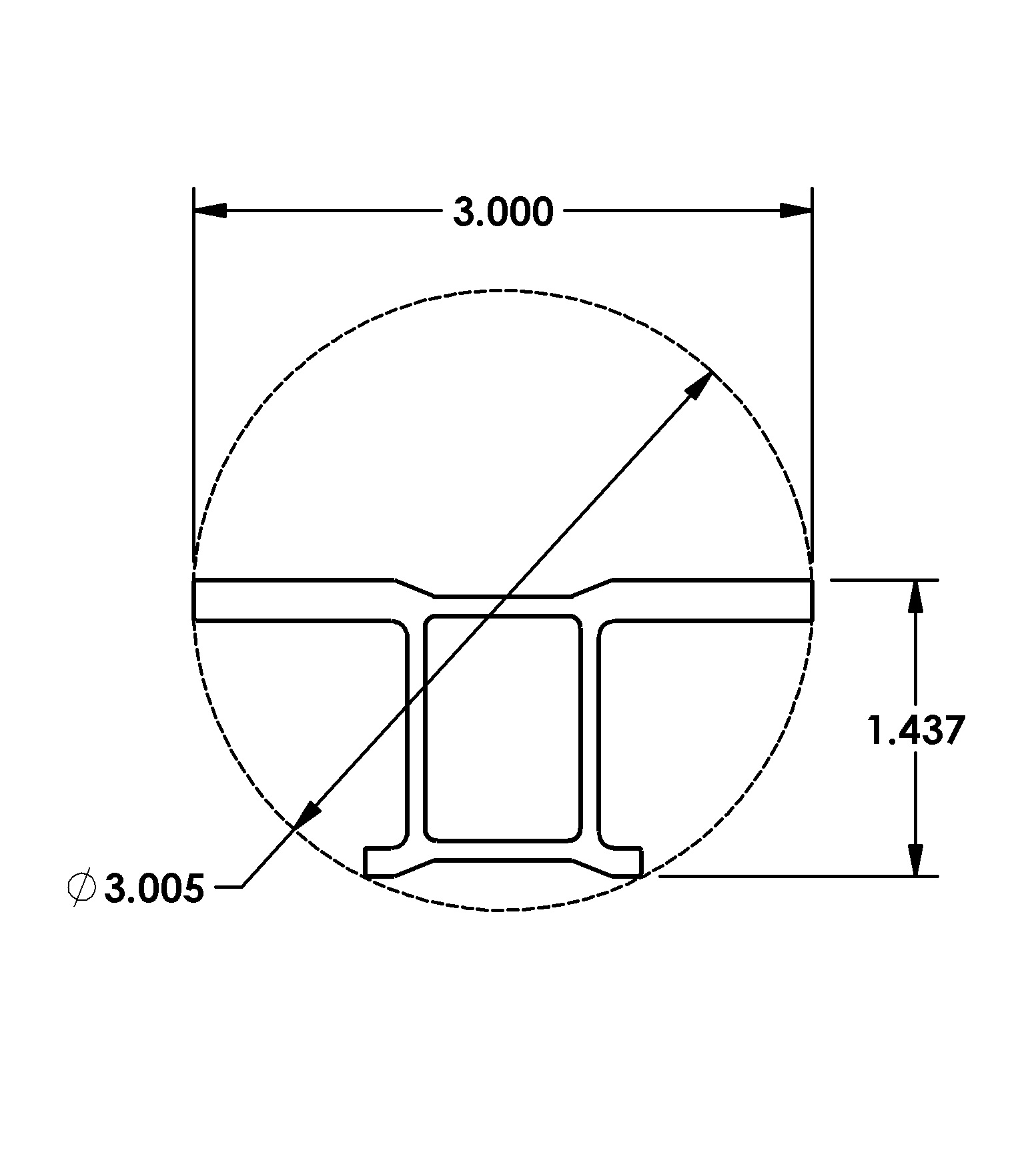

What is a Miniature Aluminum Extrusion?

If you were to look up the definition of a miniature aluminum extrusion, you’d be hard-pressed to find it, even in the Aluminum Association Standards and Data, the extrusion industry’s…

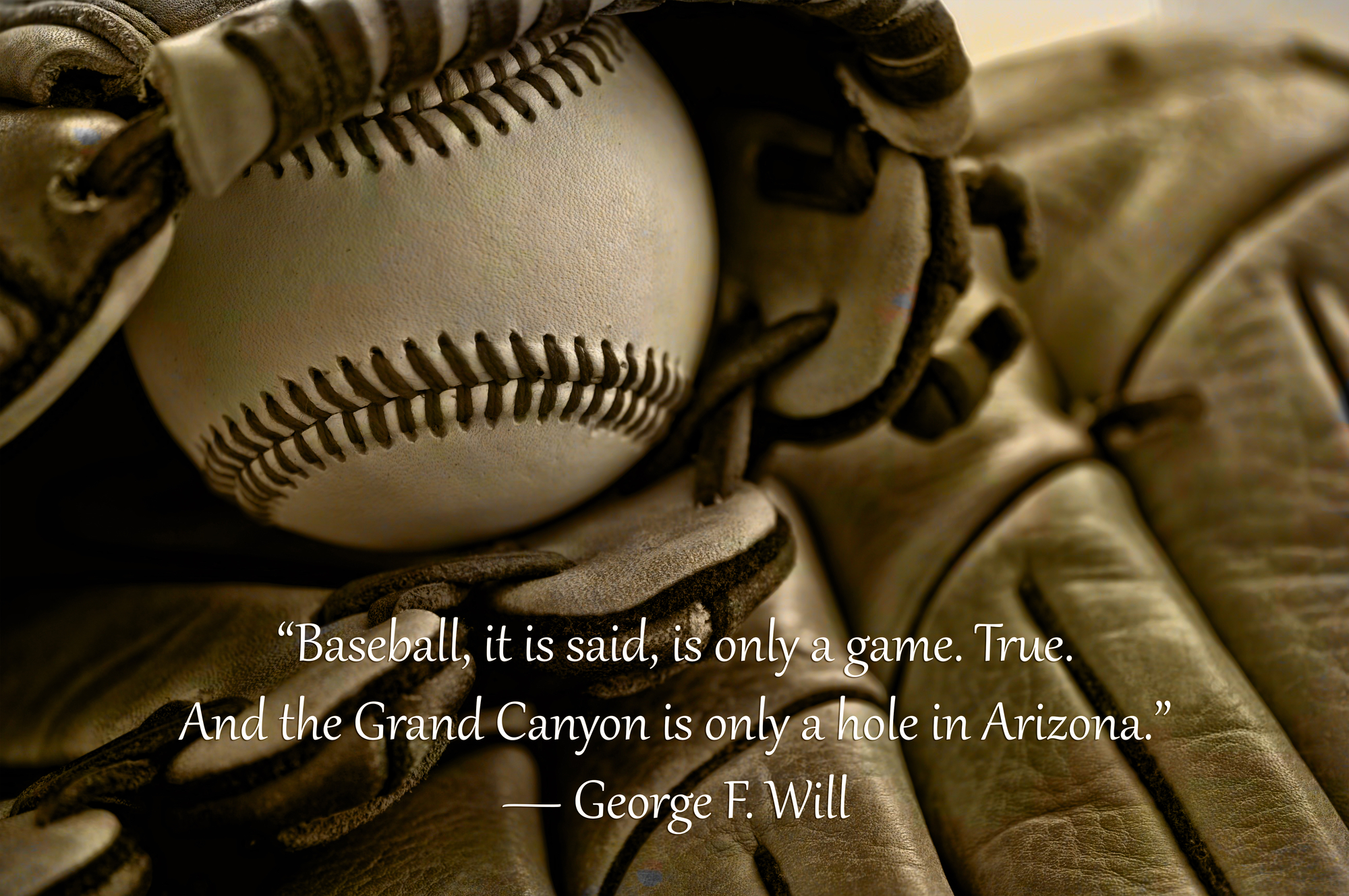

PPE Congratulates the Diamondbacks for Making the Playoffs

Early October is an exciting time for sports fans. The NFL is in full swing, the NBA and NHL training camps have started, and Major League Baseball (MLB) playoffs…

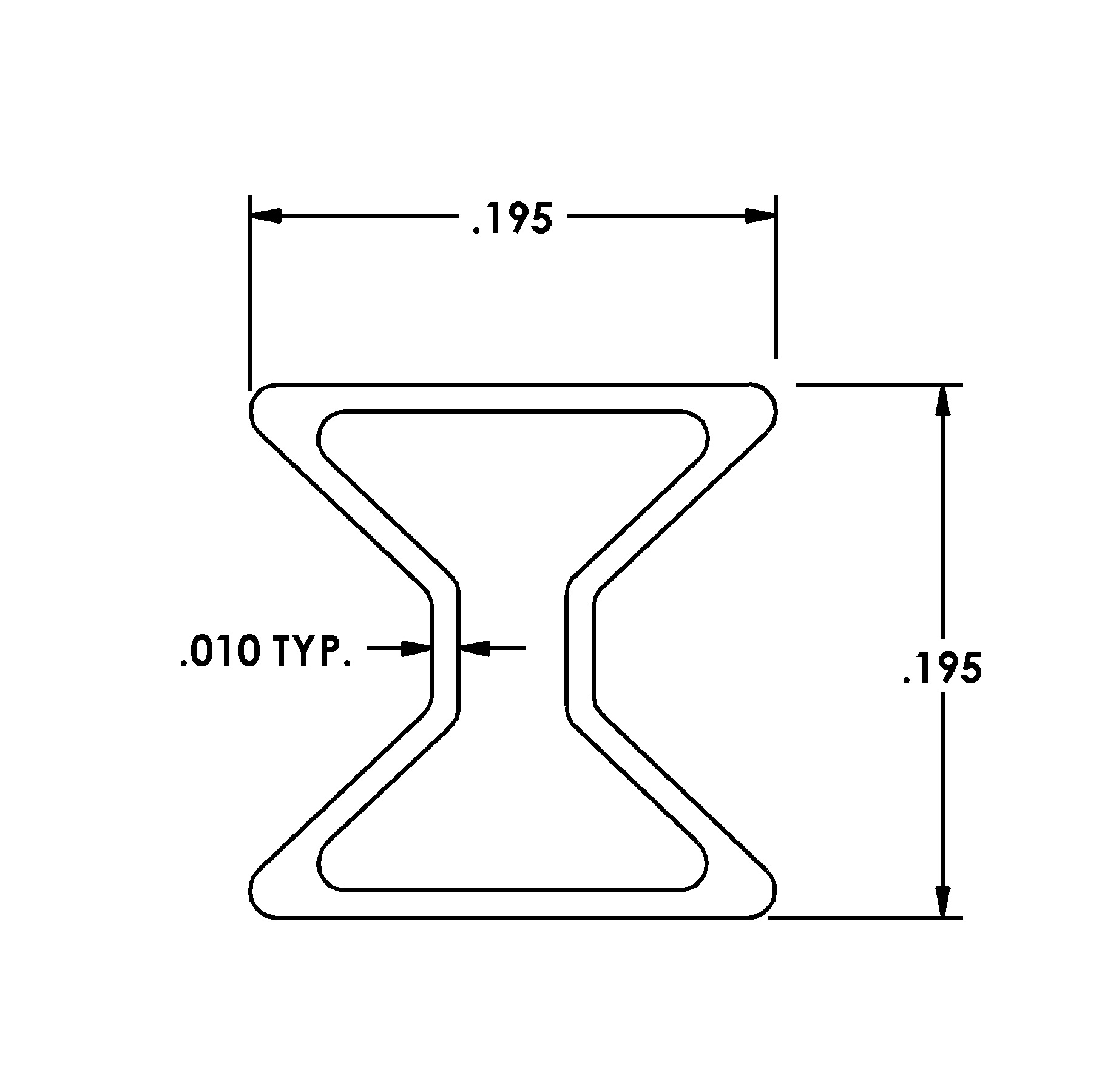

Extruded Aluminum Products – Thin Is In

One of the most common questions we are asked is "what is the thinnest wall thickness you can extrude?" The answer really depends on a few factors. For example, the…