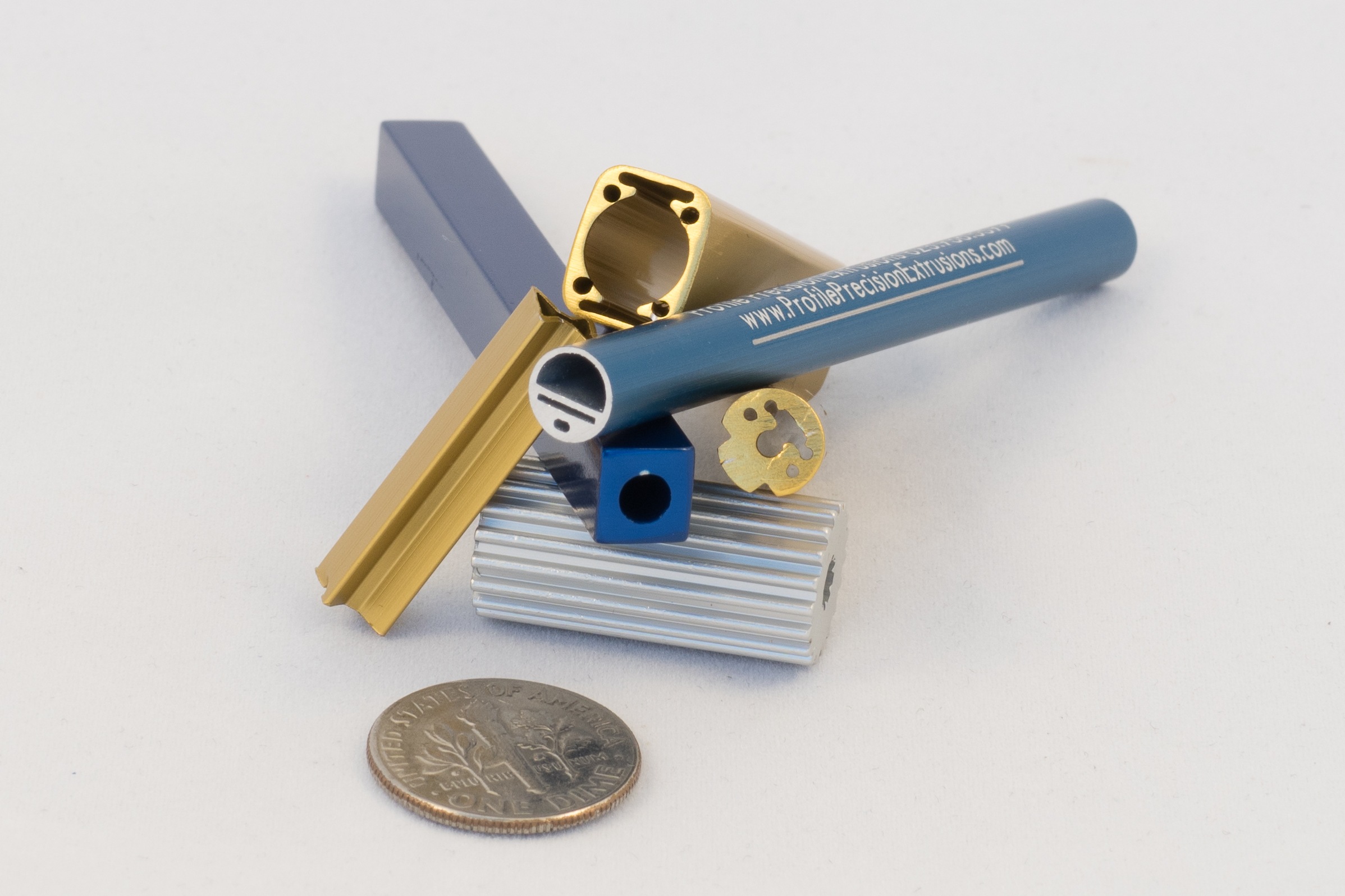

Profile Precision Extrusions reviews hundreds of extrusion design ideas each month. The designs come from a wide variety of potential customers, from entrepreneurs working at home to engineers working for large multinational corporations. We’ve put together some design tips that will help make your next aluminum extrusion project successful.

There are hundreds of aluminum alloys. We primarily work with three of the most common types which are 6061, 6063 and 3003. 6061 has the highest mechanical properties, and machines the best of the three. 6063 has mechanical properties about 30% lower than 6061. However, it has a much better surface finish and looks nicer when anodized. 3003 has the lowest mechanical properties. It is very easy to extrude so the wall thicknesses can be down to .020”. It has the highest heat transfer properties and used extensively for cooling electric car batteries.

When developing a design be sure to identify the most critical features of your design and the tolerances you’ll need for those features. This allows our production team and our tooling vendors to know what is most important for your design. That information will impact how the die is designed, produced and measured. It’s frustrating for all involved when samples ship out after 6-7 weeks of waiting only to find out that a critical feature was not identified.

Identify surfaces that are highly cosmetic. Some parts never see the light of day once they’re put into use. Others have to be perfect such as the aluminum case of an iPad or iPhone. Many times, only part of the extrusion will be seen. Knowing what surfaces will be seen helps determine how the extrusion exits the extrusion press, how it is handled on the cooling table, and how it is packed for shipment. Giving some thought to which surfaces are important will save many headaches in production down the road.

Design Rules of Thumb:

- Designs with the same wall thickness are easier to extrude that ones with unequal wall thickness

- Legs with rounded corners are easier to produce than ones with sharp corners

- A tongue ratio of 3:1 is much easier to produce than on that is 8:1

- Symmetrical parts are easier to produce than ones that are not

Profile Precision will be happy to make suggestions and give you feedback on your aluminum extrusion and extruded aluminum tube designs. We’re happy to review designs on a paper napkin, graph paper or a Solidworks file. Using the tips above we’ll work with you to make your next aluminum extrusion project a success. Ready to get started? Contact us today!