We are in the final exciting days of a 13-year journey to expand the manufacturing envelope of miniature precision aluminum extrusions. Profile Precision Extrusions announced in May that we had ordered a new extrusion press from Presezzi Extrusion based in Italy. On December 16th our new press will produce its first aluminum extrusion. Naturally we’re more than a little excited to see it run. It’s the first new aluminum extrusion press specifically built for the miniature aluminum extrusion and tube industry.

We’re excited, but what does this mean to our new and existing customers?

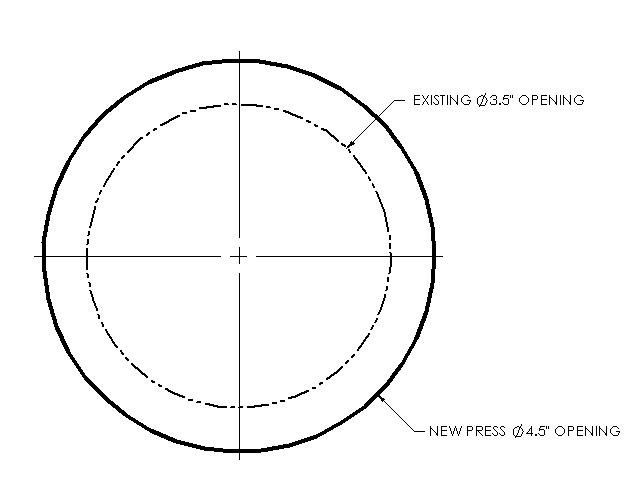

Larger parts are now possible. Our maximum manufacturing envelope (“circle size” in the aluminum extrusion world) increases by 56%. Both new and existing customers will now have access to larger, more precise parts that currently may be sourced at commodity suppliers. Switching those parts to PPE allows our customers to simplify their supplier base, reduce assembly cost by purchasing more precise extrusions, and reduce inventory costs by purchasing in smaller batches.

Larger parts are now possible. Our maximum manufacturing envelope (“circle size” in the aluminum extrusion world) increases by 56%. Both new and existing customers will now have access to larger, more precise parts that currently may be sourced at commodity suppliers. Switching those parts to PPE allows our customers to simplify their supplier base, reduce assembly cost by purchasing more precise extrusions, and reduce inventory costs by purchasing in smaller batches.- Higher precision of the parts we produce results in lower cost for our customers when they are machining or assembling their products. We’ll achieve higher precision because we specified forged frame components, prestressed tie rods and flat ways with massive shear guides and the most advanced automation electronics available. (I know, only an engineer can appreciate the last sentence!)

- 2 extrusion presses are better than one. In the past, some customers have expressed their concern that no on site back up press was available. There is now with our new Presezzi press!

- Lead times will be reduced due to increased productivity. In this world of JIT (just in time!) everything, who doesn’t love shorter lead times?

- Longer extrusions will mean less setup time. Longer extrusions will benefit those customers who have heavy parts. Up until now we could only supply our customers extrusions in lengths up to 72”. We’ll easily be able to supply 144” parts with the new press.

- Seamless tube capability for very demanding high pressure applications will now be available.

This is an imPRESSive machine that we would love for you to come by and check out. Please join us on Friday, February 3rd from 10:00 am–2:00 pm at our Open House to learn more about the precision miniature aluminum extruded shapes and aluminum tubing we manufacture.

To learn more visit our website or contact us with a question.