Are you considering utilizing aluminum extrusion for your next project? If so, it’s crucial to take the time to flesh out the details of your idea before diving into the research phase. Aluminum extrusions are widely used in various industries, making it important to determine if your idea aligns with the process. In this blog post, we will explore how to bring your aluminum extrusion idea to life.

Aluminum Extrusions are Versatile

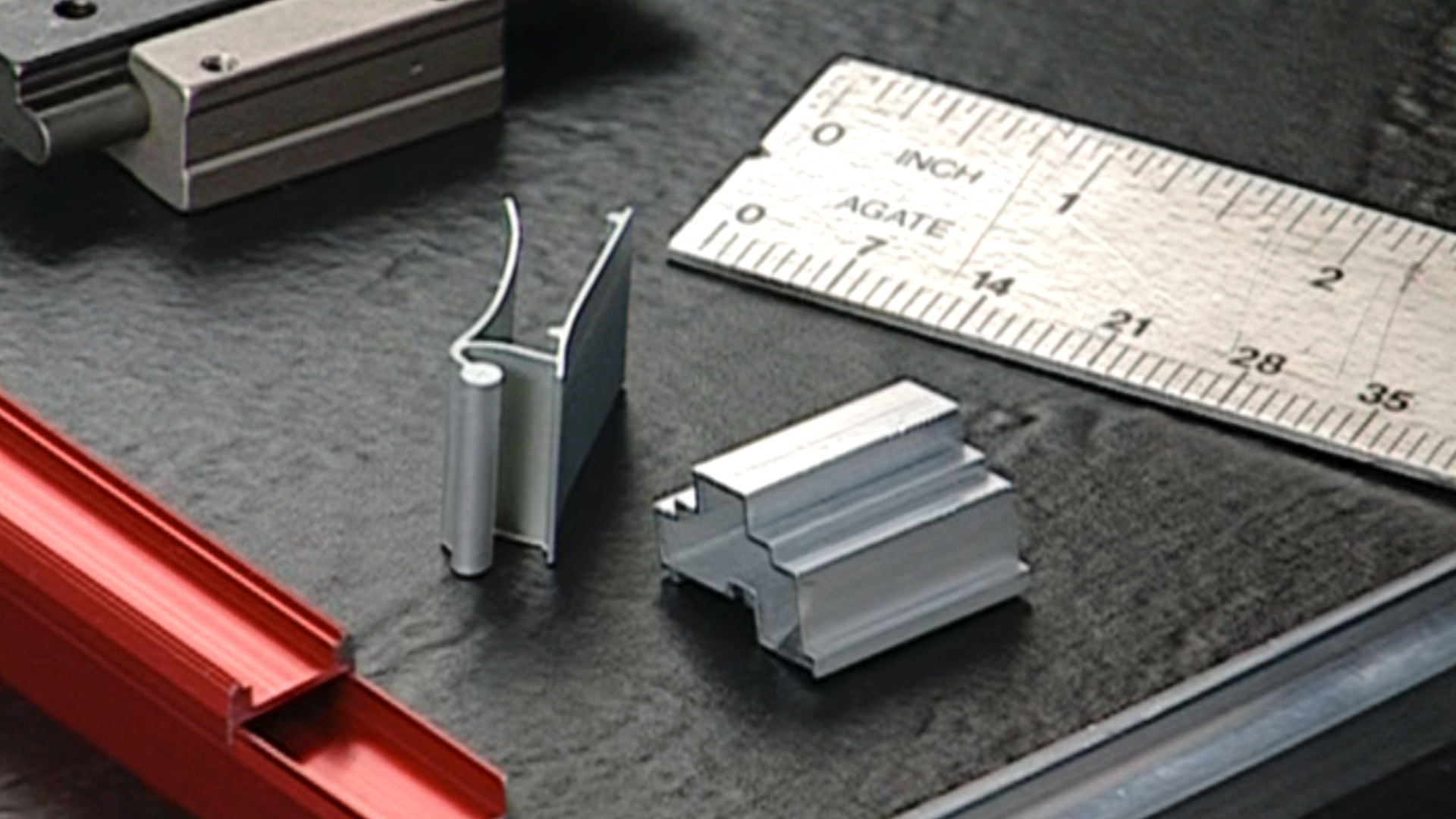

Before you proceed, it’s worth noting the extensive range of applications that can benefit from aluminum extrusions. The versatility of extruded aluminum shapes and tubing is impressive. A few examples include:

- LED lighting

- Stethoscope ear tubes

- Hinges for aircraft galleys and lavatories

- Disposable surgical implements

- Linear slides

- Bicycle wheels

- Heat pipe cooling systems for satellite electronics

- And more!

Seeking Guidance from Potential Partners

The best way to determine feasibility is to consult a future partner. There are hundreds of extrusion mills in North America. However, not all designs are a good fit for the process or a particular mill. Reach out to them and describe your project in detail. For simpler shapes like round tubes or square bars, a concise description might be sufficient. For more complex geometries, sketch your design on paper, scan it, and email it to potential partners. In cases where the design is intricate, providing a CAD file can be immensely helpful. Be patient, it may take talking to three or four mills to find the right fit.

The Role of Profile Precision Extrusions

At Profile Precision Extrusions, we have evaluated thousands of designs to assess their compatibility with the extrusion process. Sometimes, an idea might align with the process but not with our specific equipment. In such instances, we are more than willing to suggest other companies within our industry that could potentially assist you. Our ultimate goal is to see your project succeed, even if it means collaborating with someone else.

Addressing Design Challenges

While some designs may fit our capabilities, they might push the boundaries of what can be produced through extrusion. In such cases, we believe in providing honest feedback. We will inform you if your ideal design poses challenges and suggest modifications to make it more extrusion-friendly. Often, designers are willing to make the necessary adjustments to ensure successful extrusion. However, there are instances where the designer insists on proceeding despite the low probability of success.

Navigating Challenges: An Example

To illustrate the complexities involved, we took on a highly challenging extrusion project recently. Despite our best efforts, we were unable to produce acceptable extrusions. We were unable to get all sixty rectangular voids the same size. The aluminum making up the six nodes flowed at a faster rate during extrusion, making it impossible for us to have all sixty voids exactly the same. This example highlights that even with the right equipment, certain designs can present significant hurdles. It’s crucial to collaborate closely with your chosen extrusion partner to understand and overcome, if possible, such obstacles.

Fleshing out your aluminum extrusion idea is a crucial step in the journey towards bringing your vision to life. By thoroughly detailing your concept and seeking input from experienced professionals, you can ensure the feasibility and success of your project. Remember, Profile Precision Extrusions guides you throughout the process, from design evaluation to suggesting modifications and bringing your idea to life. Embrace the challenges, stay open to adjustments, and let your aluminum extrusion idea shine.

Contact us today to find out if we can partner together to bring your aluminum extrusion idea to life!