When evaluating materials for bike wheel construction, engineers and product teams face the tradeoffs between carbon fiber and aluminum—each with distinct implications for product performance, reliability, cost, and manufacturability. While…

Miniature Aluminum Extrusions in Aerospace: Precision, Lightweight Solutions for Complex Designs

Miniature Aluminum Extrusions in Aerospace: Precision, Lightweight Solutions for Complex Designs The aerospace industry demands components that are both lightweight and incredibly strong. Miniature aluminum extrusions have emerged as a…

Understanding Aluminum Coatings: Type II vs. Type III Anodizing

When it comes to enhancing the properties of aluminum extrusions, anodizing stands out as a versatile and effective method. Profile Precision Extrusions (PPE) offers two primary types of anodizing: Type…

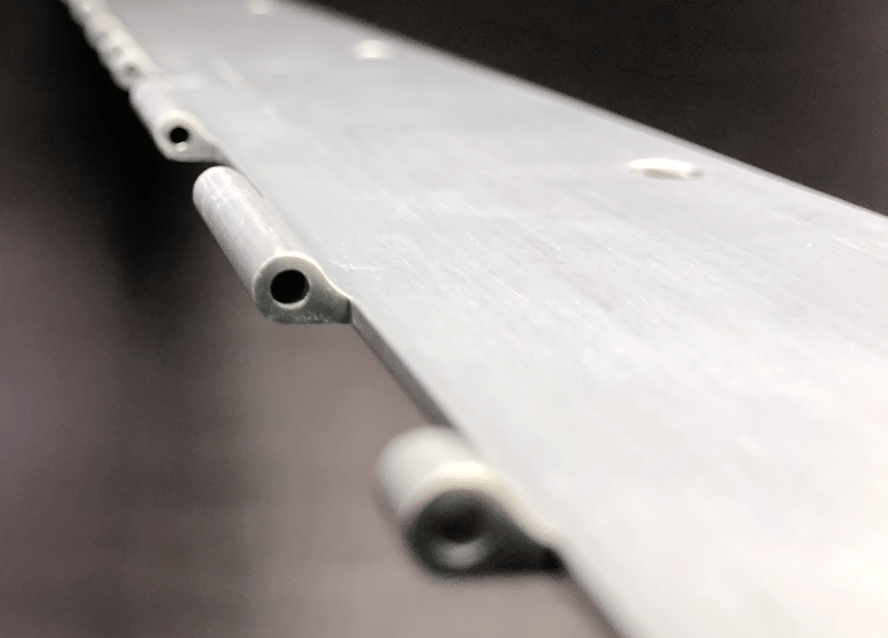

Extruded vs. Seamless Drawn Aluminum Tubes: Choosing the Right Type for Your Needs

Tubes are produced using two methods. The production method chosen plays a pivotal role in defining the tube's properties and its applicability across various sectors. The choice between extruded and…

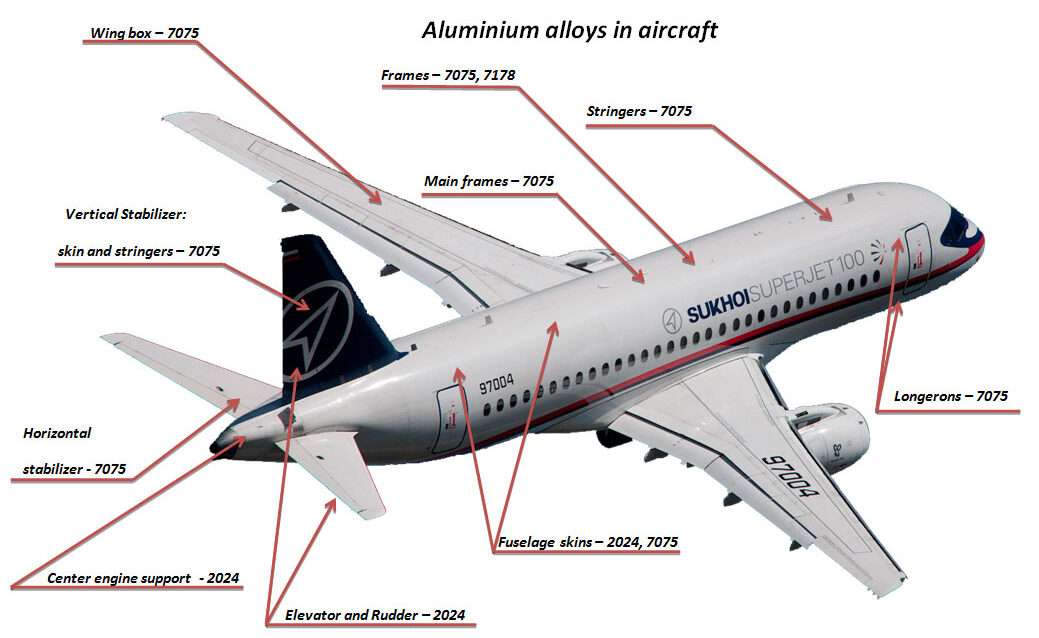

Lead Time For 7075 and 2024 Aluminum Alloy Extrusions Is Over 1-Year!

Profile Precision Extrusions is contacted at least two or three times each day by companies looking for extrusions made from 7075 or 2024 alloys. These high-strength alloys are used extensively…