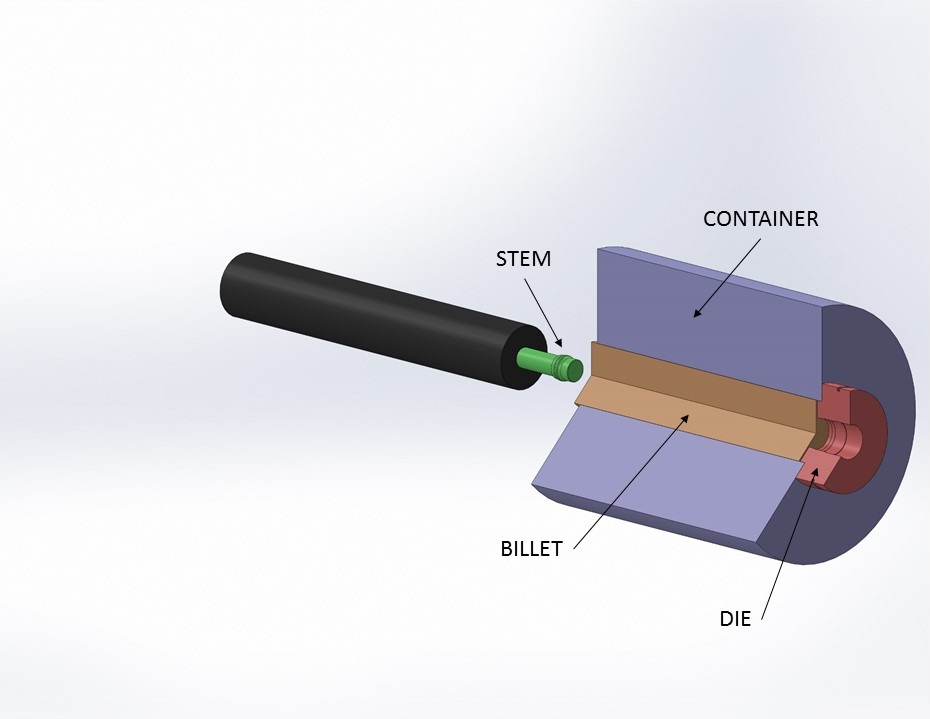

In our last blog we described how structural, or porthole, tubes are formed during the extrusion process. Structural tubing has weld seams that are a result of the extrusion billet…

Aluminum Porthole Tubing Forms: Seamless vs. Structural Part 1

Over 54% of the extruded aluminum Profile Precision manufactures each year has a hole in it, on purpose, and some have more than 1! The tube is commonly referred to…

New Swiss-Type CNC Lathe Improving Custom and Medical Extrusions

In our July 2016 blog we shared some of the capital equipment investments Profile Precision Extrusions has made to support our customer projects over the past 4 years. Citizen’s Swiss-type…

Larger Precision Aluminum Parts Now Possible With New Presezzi Extrusion Press

We are in the final exciting days of a 13-year journey to expand the manufacturing envelope of miniature precision aluminum extrusions. Profile Precision Extrusions announced in May that we had ordered a…

Medical Device Design – Why Extruded Aluminum Components are a Great Choice

Medical device engineers may want to consider aluminum extrusions and tubing because of its biocompatibility with the human body. It’s easily machined, can be easily formed in the annealed state,…