Demand for aluminum extrusions during the first five months of 2021 is at unprecedented levels. Industry lead times for delivery of new orders are up to 27 weeks. Some aluminum extrusion manufacturers are not accepting new customers or new custom aluminum extrusion designs from existing customers! At Profile Precision Extrusions we are happily adding new customers and looking forward to working with them well into the foreseeable future. Demand for our precision miniature aluminum extrusions and fabrication is very strong. As a result, lead times are about twice as long as they were 24 months ago and prior to CV-19. Due to the extended lead times, it’s more important than ever to understand how long it will take to translate your idea into a finished extrusion.

Step 1: Creating a Die

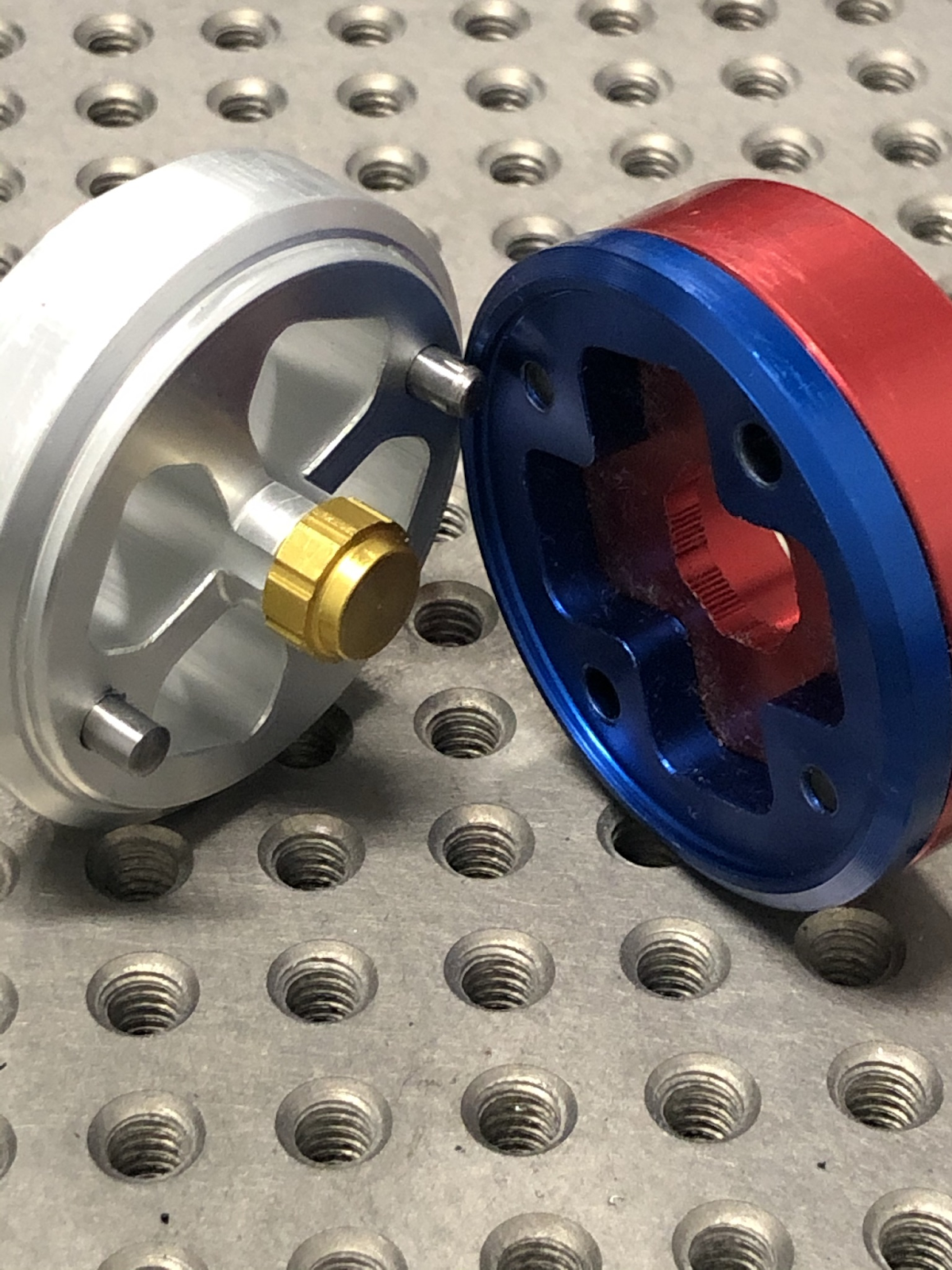

To produce your design aluminum must be pushed through an extrusion die. The die is machined from H-13 tool steel. For simple geometries like an angle, tee, or zee a 1-piece die is fabricated. The current lead time for 1-piece dies is 3 weeks. For hollow tubes, a 2-piece die is fabricated. One of the pieces is a mandrel that forms the inside diameter of the tube, the other piece forms the outside diameter of the tube. It’s currently a four-week period to machine a 2-piece die, as seen below, for tube designs.

Step 2: Creating Samples

Once the toolmaker has completed fabrication of the die, extruded samples are produced so the customer can check the form, fit, and function of the actual parts. Producing extruded samples for designs with a simple geometry and generous tolerances takes one try in most cases. For complex geometries or very challenging tolerances the process of dialing in the extrusion die can take 3-4 attempts. The mill will take information learned from unsuccessful attempts and will make adjustments to the die or production parameters until the samples match the customer design. Producing acceptable samples can take from a few days to weeks.

Step 3: Deciding on Finishing Touches

One also should keep in mind that samples requiring value-added processes such as machining, anodizing, or powder coat paint will take additional time. A good rule of thumb is to add 2-3 weeks for each required process. Make sure you ask your mill about the lead times for the various processes. Don’t hesitate to ask for the mill to expedite the various processes. Make sure that if you do ask for an expedited delivery of samples you give them a reasonable date for receipt. Asking for a specific date to receive samples is much better than just stating “I need my samples ASAP.”

For more information about the extruded aluminum shapes and tubing design process, download our free guide “7 Steps to Bring Your Aluminum Extrusion Idea to Life” today. To speak with someone in real-time, call Profile Precision Extrusions in Phoenix at (623) 936-5599 with your idea, sketch, or CAD file. We’ll be happy to review your design with you either over the phone or via video call.