We often joke here at Profile Precision that all we get are the extrusions no one else will make. In reality, unless you’re pushing the envelope of what is possible you will never get any better at what you’re doing. It’s true for kids in elementary school, professional sports teams, and even aluminum extrusion companies. This Fall, we had two projects with very diverse applications challenge us. The first is an extruded aluminum tube used in oxygen concentrators for individuals with respiratory conditions. The second is an extruded aluminum shape used in shared electric scooters that have been in the news recently.

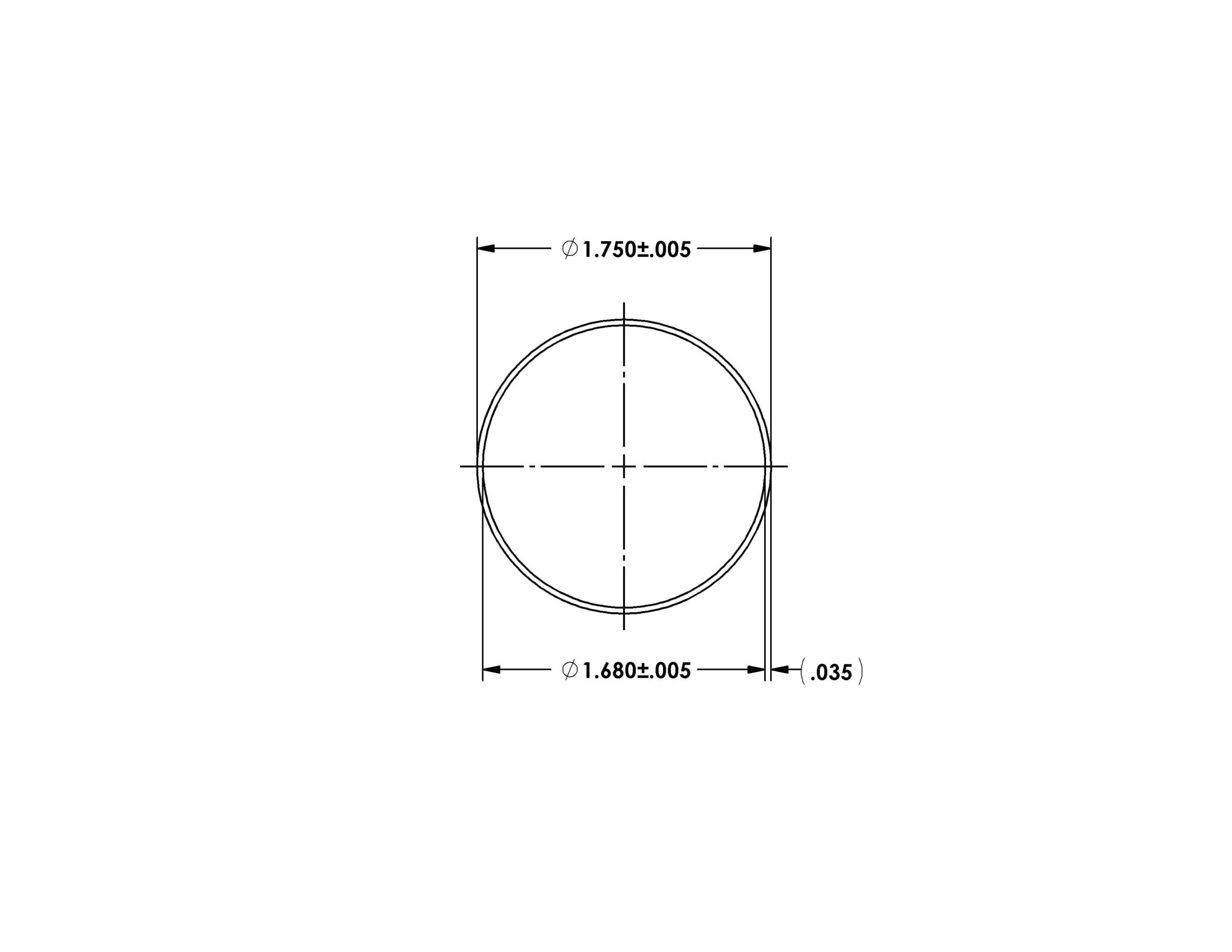

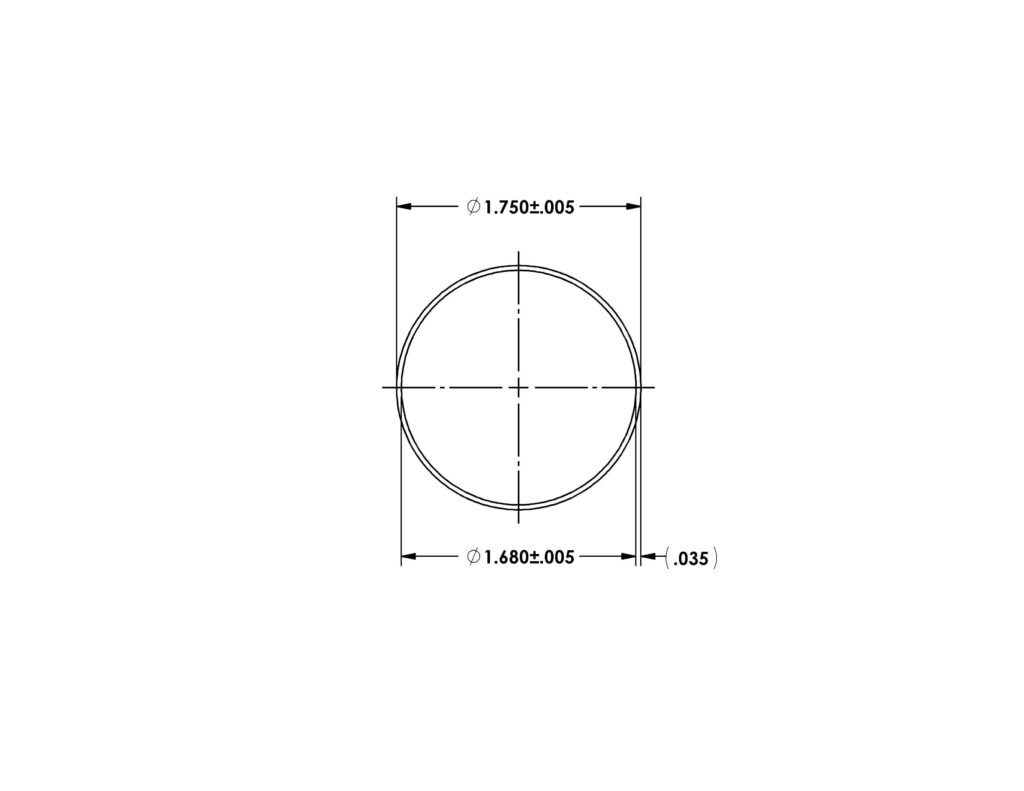

Our first project challenge was with an extruded aluminum tube used for oxygen concentrators. The round tube below is challenging due to the combination of the outside diameter, the wall thickness, and their respective tolerances. This tube would be fairly easy to extrude if the outside diameter was .750”. Doubling the OD (outside diameter) makes it very difficult to keep the tube round. The tube wants to exit the extrusion press in an oval shape rather than round because the walls are so thin (.035”). The project was a good opportunity for us in the medical industry. For those reasons, we wanted to give it a try. We felt our new 5” extrusion press would be up to the challenge. We were excited when we produced intolerance samples on the first try. We sent them to the customer and anxiously awaited their feedback. Much to our surprise, the samples were rejected. What we didn’t know was that the customer wanted a Cpk of 1.33 on the outside and inside diameters! For those of you that are not Quality Engineers, what the customer was saying in effect is that they really needed a tolerance on the OD and ID of ±.003”, rather than the ±.005” that was on their specification. A reduction in variation of 40%! A very difficult project just became nearly impossible. After digesting that piece of good news, we sat down and asked ourselves if what the customer was asking for could be done. Our ace in the hole was our recently installed 5” extrusion press. It has amazed us with its precision from time to time. So, we decided there might be a chance to produce the tube with the tighter tolerances. We reworked the extrusion die to optimize its performance. We also optimized the production parameters. We then ran a controlled extrusion experiment, and randomly picked 50 pieces to measure on our CMM. Much to our delight, we produced tubes that exceeded the 1.33 Cpk the customer was requiring!

Much to our surprise, the samples were rejected. What we didn’t know was that the customer wanted a Cpk of 1.33 on the outside and inside diameters! For those of you that are not Quality Engineers, what the customer was saying in effect is that they really needed a tolerance on the OD and ID of ±.003”, rather than the ±.005” that was on their specification. A reduction in variation of 40%! A very difficult project just became nearly impossible. After digesting that piece of good news, we sat down and asked ourselves if what the customer was asking for could be done. Our ace in the hole was our recently installed 5” extrusion press. It has amazed us with its precision from time to time. So, we decided there might be a chance to produce the tube with the tighter tolerances. We reworked the extrusion die to optimize its performance. We also optimized the production parameters. We then ran a controlled extrusion experiment, and randomly picked 50 pieces to measure on our CMM. Much to our delight, we produced tubes that exceeded the 1.33 Cpk the customer was requiring!

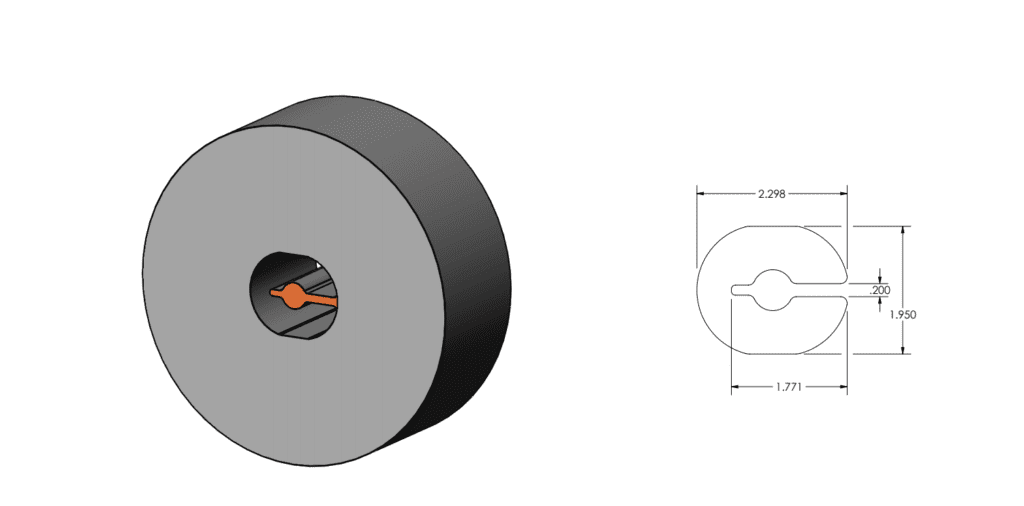

Our second challenge this Fall was to extrude the shape below. The completed part goes on one of the electric scooters that have sprung up in city centers and college campuses recently. The challenges with this part are its size and the design in general. It is a very heavy part for us at Profile. In addition, the design is not extrusion friendly. A relatively thin piece of steel must form the void. It must withstand a tremendous amount of pressure as the aluminum is forced through the extrusion die. The design had been turned down by other aluminum extrusion plants. We thought we had a chance to successfully manufacture the part utilizing a unique type of extrusion die. Working closely with our toolmaker Thumb Tool, we developed an extrusion die with thought might work. Over the course of 4 weeks in late July & early August, the original die design was tested, refined, and tested again. In September and October, we shipped over 1000’s of parts to our customer.

Our customer was so happy with the results that they’ve thrown us another challenge. Use a 30% stronger alloy, which will put even more stress on the small thin piece of steel due to even higher extrusion pressures required for the new alloy. Our initial results in late October look promising.

Do you have an extrusion design that you’ve been told can’t be extruded? If so, let us take a look at it. We’re always up for a good challenge. Contact us today!