Profile Precision Extrusions has many things to be thankful for as 2020 dawns. Great employees who work very hard. A safe, clean, well-maintained workplace. Investments in new equipment and processes to support customer requirements. And last but not least customers that have tough requirements, are fair in their dealings with us, and most importantly challenge us to get better every day.

Each year we add around fifty new customers that range in size from the largest corporations to entertainers working on their “next big thing”. Three of our newest customers are profiled below:

Scandium International Mining Corp. (SCY)

SCY was introduced to Profile Precision by our metallurgical consultant Rob Pahl of Metalink, LLC. SCY is in the process of developing a primary scandium mine in Australia. Scandium is often considered a rare earth element (REE) and usually is produced in small quantities as a byproduct of other mineral refining processes. Additions of small amounts of scandium improve the grain structure of aluminum alloys, resulting in higher strength aluminum parts and extrusions, desired in aerospace, automotive, and consumer goods industries.

Profile Precision worked with Metalink to develop a customized extrusion plan for this project, where we formed a small diameter aluminum extruded rod, using SCY’s high strength specialty alloy. After extrusion, the rods were coiled around a drum and sent to the Colorado School of Mines for further processing into wire.

Profile Precision’s ability to both customize production parameters and produce small quantities of extrusions is particularly useful to companies conducting new or specialized alloy development projects and for prototyping of new products for all industries. Pets & Wheels

Pets & Wheels

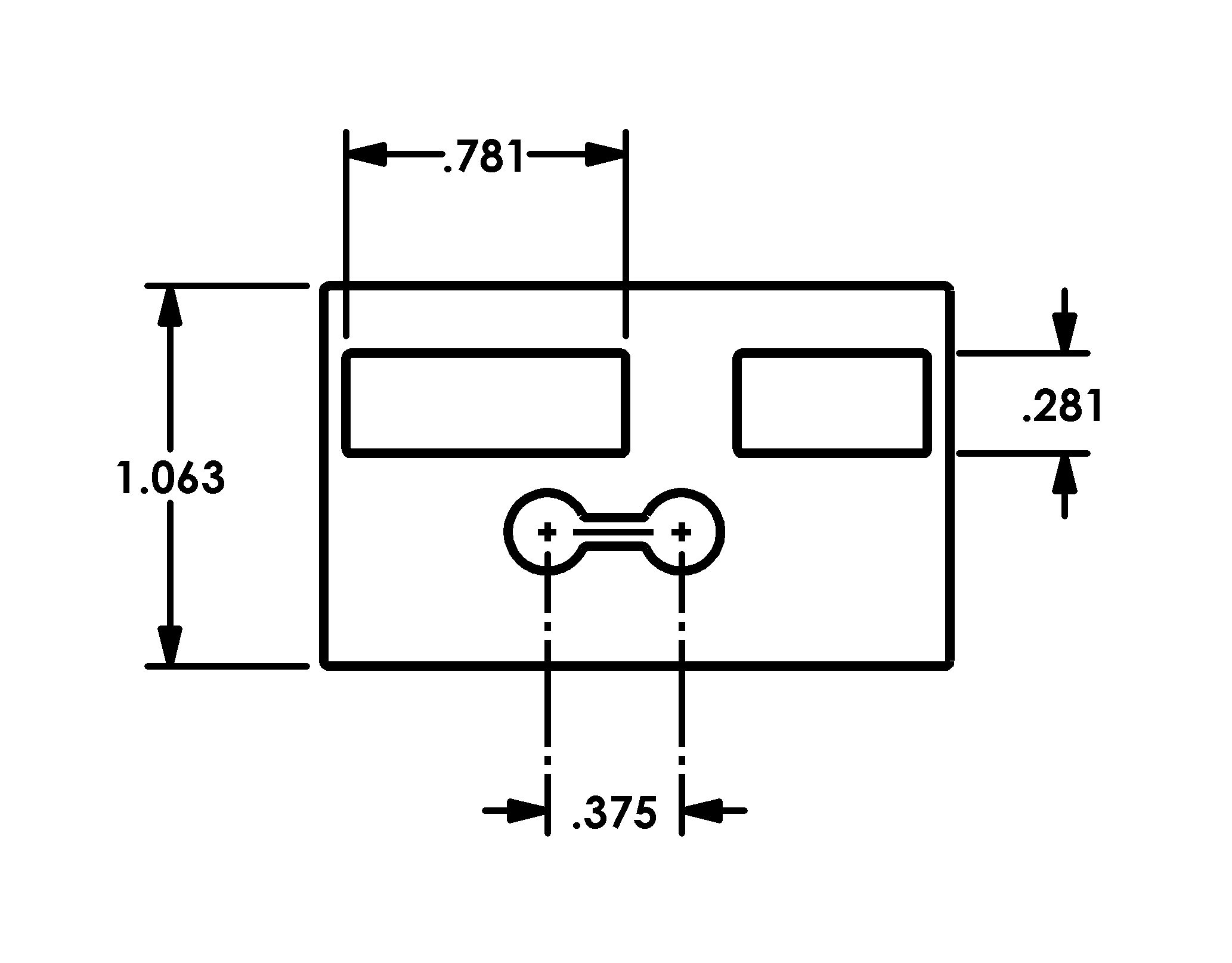

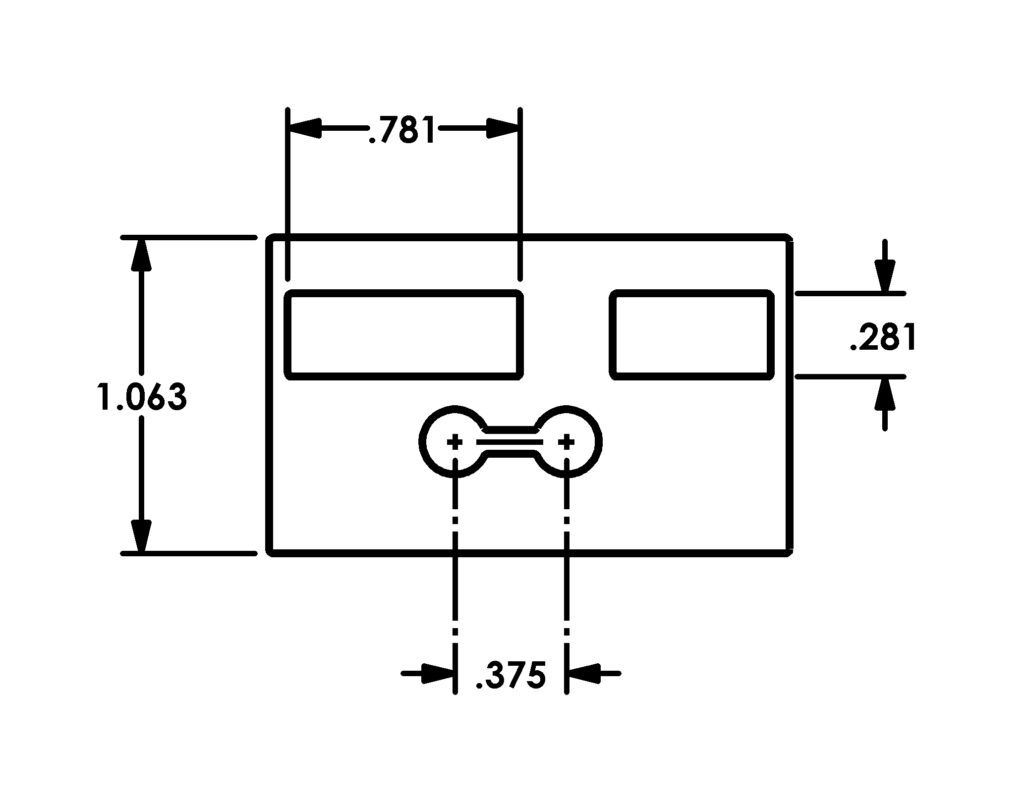

Pets & Wheels is a Tucson, Arizona based company that makes wheelchairs for animals who have lost the use of their hind legs. They contacted us to help design and prototype a new component. The goal was to combine (2) machined components into (1) aluminum extrusion. Our team made numerous suggestions on 3 design revisions to help develop the final design. The aluminum extrusion was successfully prototyped in November.

Smithsonian Institution

The world-renowned collection of museums and galleries contacted Profile Precision to assist in designing aluminum extrusions for a special display case for an exhibit of gold artifacts from Africa. One of the stipulations from the owner is that the artifacts not come into contact with wood. The Smithsonian typically displays artifacts in wooden cases. This necessitated the need for an alternate material. Aluminum extrusions were identified as a good alternative to wood. Profile’s team worked with Smithsonian Exhibits Specialists to make suggestions to their original design. Samples are scheduled to ship in early 2020.

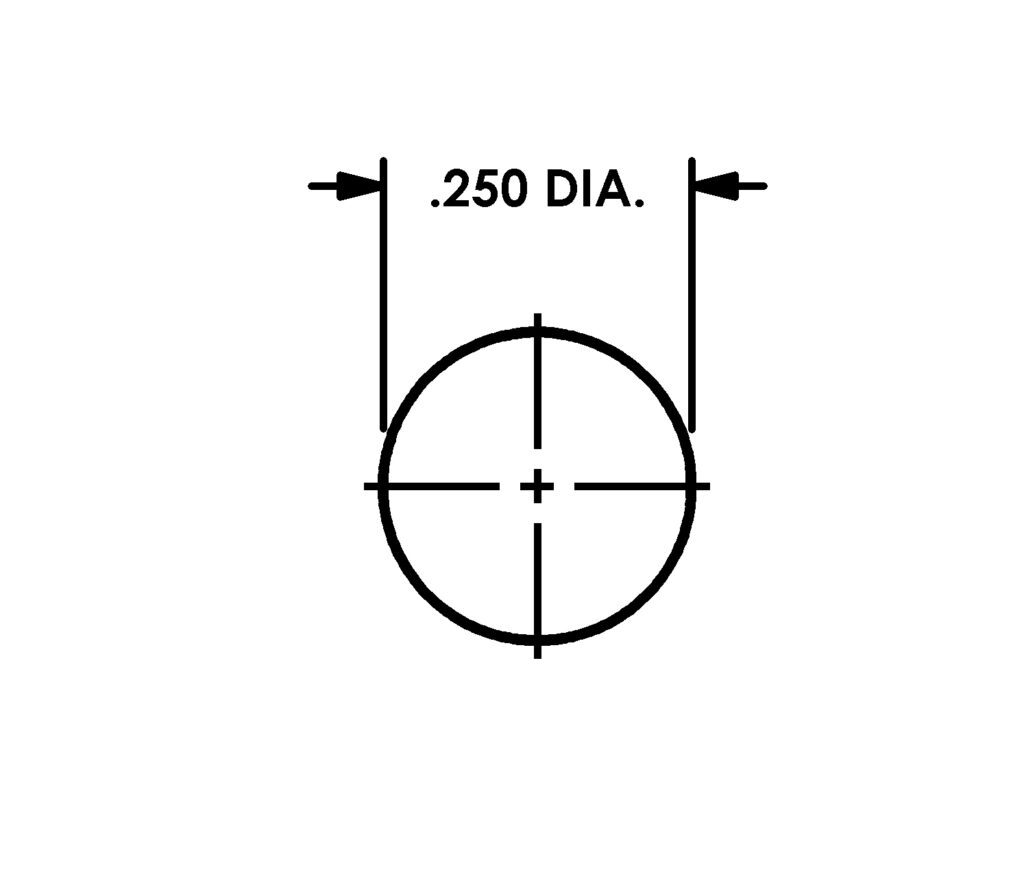

Profile Precision Extrusions believes that no project is too small however, some designs can be too large for our equipment. If your design fits inside a 4.25” diameter circle, we can probably extrude it. We have no minimum order size and can produce extrusions with wall thicknesses down to .020”. We’ll work with on dimensional tolerances that fit your needs, not just industry standard. Contact us today to find out more about how Profile Precision can bring your aluminum extrusion design to life.