Profile Precision Extrusions supplies its customers with a wide variety of value-added services. In many cases, our customers would prefer to purchase a component ready for assembly rather than raw material that needs further processing internally or at another vendor. Over 70% of our orders involve additional processing of our aluminum extrusions and tubing. For example, each month we cut over 500,000 pieces to length on our three precision saws. An unusual service we offer is centerless grinding of aluminum tubing. Purchasing a component allows our customers to save money by minimizing their supplier base and shortening their overall lead time.

Cutting or machining aluminum extrusions generally result in a burr being left on the part after the operation is completed. In many cases, the burr needs to be removed. One of the most cost-effective methods is vibratory deburring. The cut aluminum pieces are placed in a vibrating bowl with plastic or ceramic media. The media quickly and effectively remove burrs from the parts. The process also includes the use of a small amount of soap which cleans the parts by removing the lubrication used during cutting or machining. Another important benefit of vibratory deburring is the parts have a very uniform surface finish. The uniform finish improves the cosmetic look of the parts if they are anodized.

[embedyt] https://www.youtube.com/watch?v=F0fw-kWqIZ8[/embedyt]

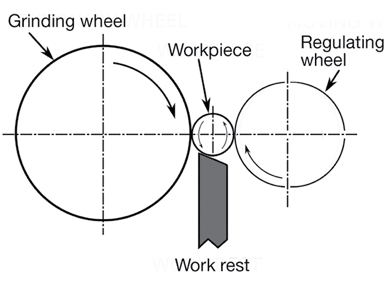

Centerless grinding is an unusual but very effective method to produce very precise tubes. It is a machining process that uses abrasive cutting to remove aluminum from the outside diameter of an aluminum tube. Be sure to follow the link to our YouTube video because a picture (video) really is worth a thousand words. Centerless grinding is typically ordered by our customers who use swiss style CNC lathes to machine very precise parts. To be successful, the incoming raw stock must be very precise and consistent. Profile Precision typically extrudes aluminum tubes under .750” OD to a tolerance of ±.003”. Utilizing centerless grinding the OD tolerance can be improved to ±.0005”!

If you’re working on a new design that requires an extruded aluminum shape or thin wall aluminum tubing contact Profile Precision Extrusions today. In addition to bringing your design to life, let us save you money and time by supplying a finished component.