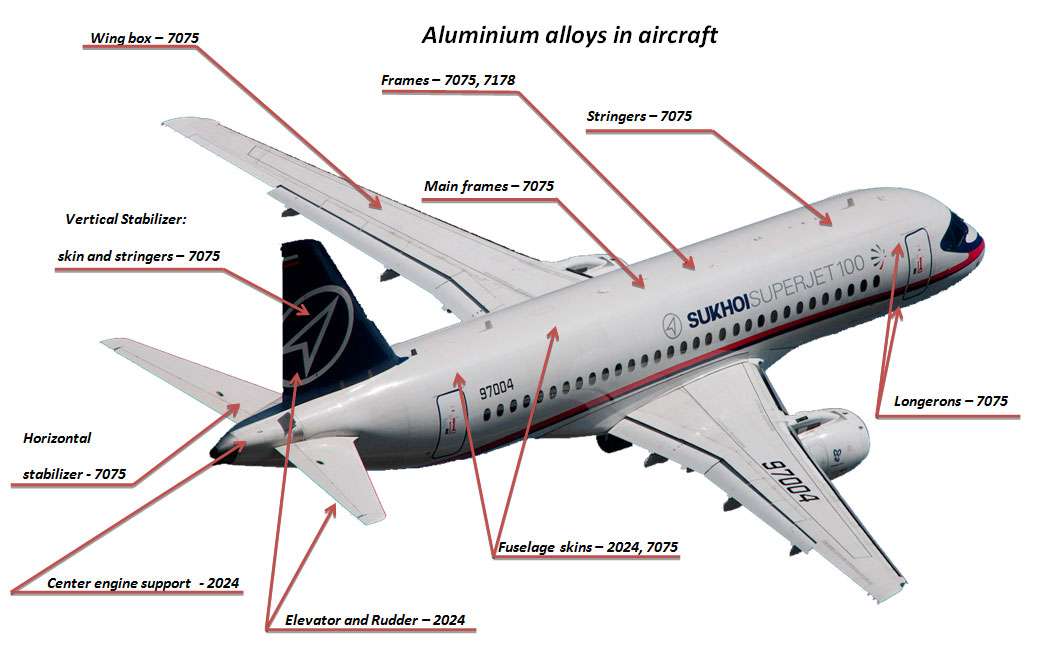

Profile Precision Extrusions is contacted at least two or three times each day by companies looking for extrusions made from 7075 or 2024 alloys. These high-strength alloys are used extensively in the wings and fuselage of commercial aircraft due to their high strength-to-weight ratio and excellent fatigue resistance. They are also known as hard alloys in our industry due to their high strength and difficulty in extruding. Unfortunately, PPE hard alloys require separate solution heat treatment and specialized straightening and de-twisting equipment which we do not have.

Here is an alphabetical list of extrusion mills that specialize in hard alloy extrusions.

- Arconic, Lafayette IN

- Falco, Chandler AZ

- Kaiser Aluminum, Chandler AZ

- Taber Extrusions, Russellville AR

- Universal Alloy Corporation, Canton GA

WHY ARE LEAD TIMES SO LONG?

Coming into the CV19 pandemic Airbus and Boeing had been delivering record numbers of airplanes. Their order books we full for many years into the future. Covid spread around the world in 2020 and airline travel came to a stop. Airplane production was severely curtailed as a result. In mid-2022 as travel picked up both companies resumed production and airlines saw a significant increase in travel demand. They wanted all those planes they had on order prior to CV19! Global disruptions to the aircraft supply chains slowed the ramp-up in build rates. Since mid-2023 both Airbus and Boeing are planning for record deliveries in 2024 and beyond. Unprecedented high demand for a very challenging product to produce results in long lead times.

I CAN’T WAIT A YEAR, WHAT CAN I DO?

- Consider re-evaluating your choice of alloy. Lead times for 6061 aluminum extrusions are very short in comparison to hard alloy lead times. Less than 8 weeks in many cases.

- Contact a local or national metals distributor. Some of them stock the more popular AND (Army/Navy Designs) and BAC (Boeing) designs. You may have to contact 4-5 of them.

- Machine your extrusion from bar stock. While very expensive, if you can’t wait it is an option to consider.

Profile Precision Extrusions has also seen an increase in demand for our 6061-T6511 and 6063-T6 extrusions from the aircraft market. We supply extrusions used in the LED interior lighting systems, brackets that hold up overhead bins (that we all fight for prime boarding positions to use), and brushed and anodized trim used in galleys and structural extrusions and hinges for lavatories. While the lead times for hard alloy extrusions may be daunting, we are experts at a wide variety of aluminum extrusion projects, and our lead times are much shorter. If you have a new product design and would like to work with a team that has helped to develop over 5000 extrusions. Contact Us today.