Here at PPE we regularly review our digital marketing efforts to understand why potential customers come to our website and how we can provide relevant information to them. In reviewing the data from January to June of this year two interesting facts emerged. First, one of our most popular blogs this year was actually published in 2017, The Advantages Of Aluminum For The Medical Device Industry. Second, many searchers this year are wondering about the biocompatibility of aluminum so that’s our queue to create another medical device industry-related blog.

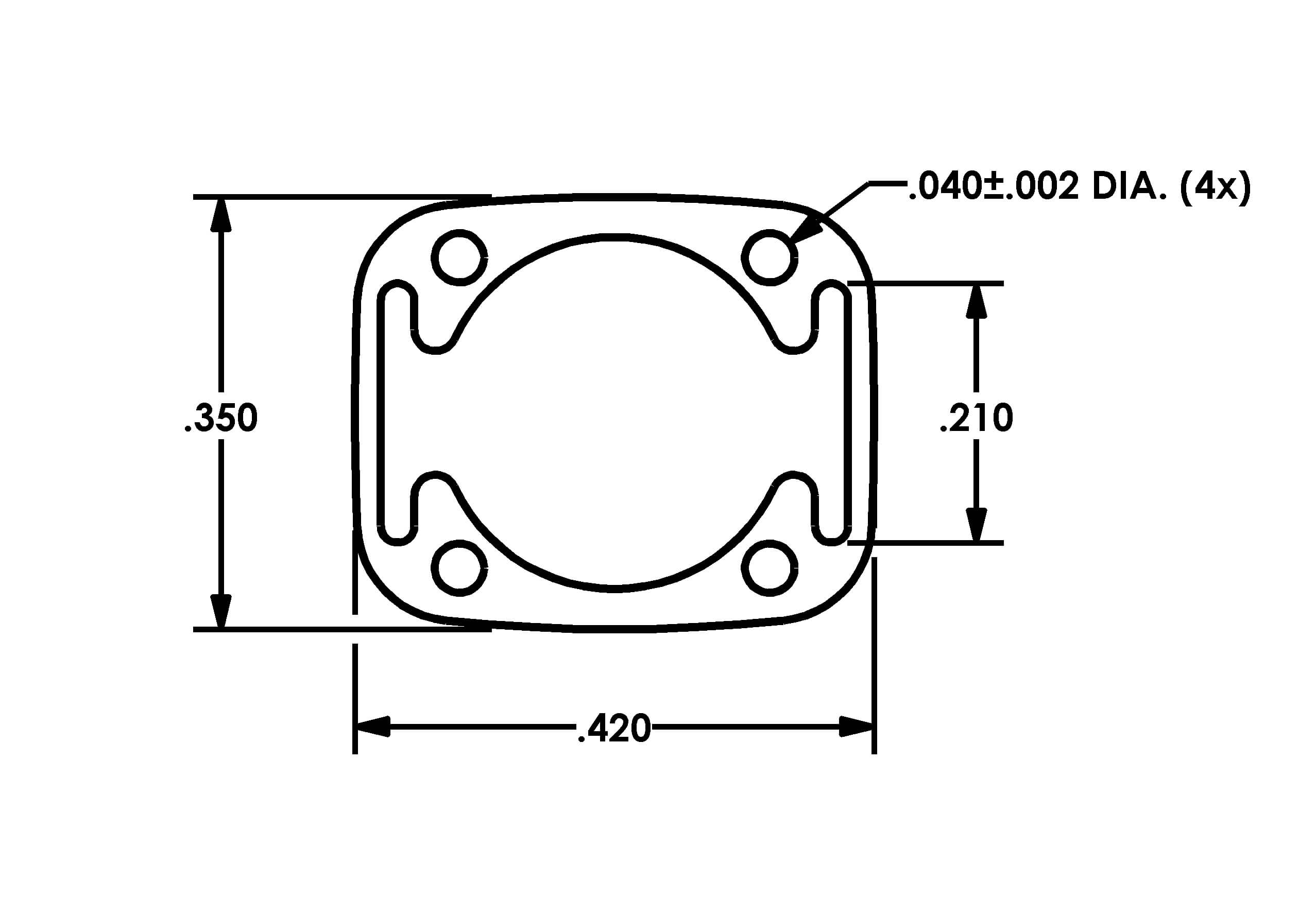

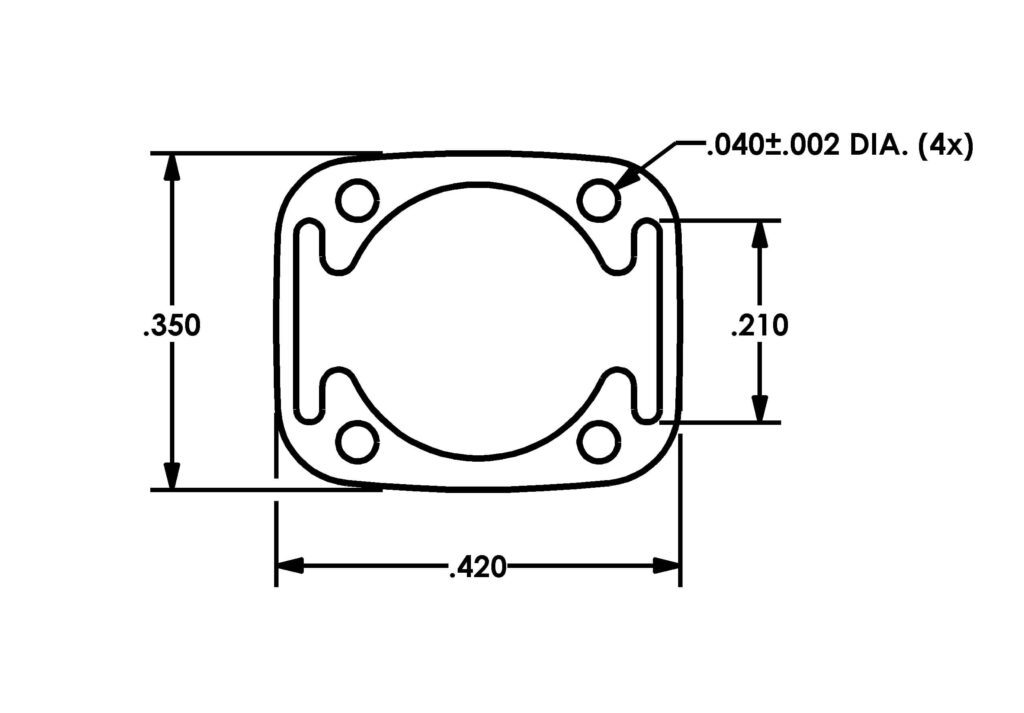

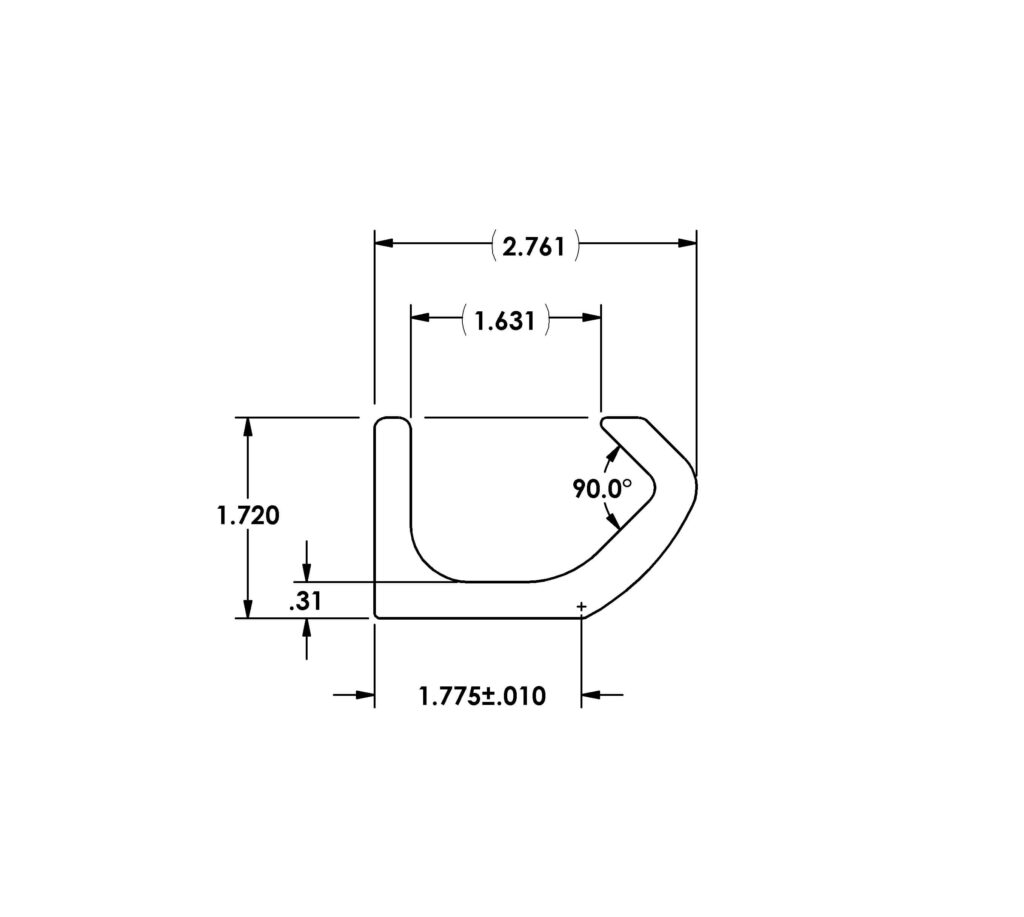

3 advantages of aluminum extrusions to the medical device industry are design flexibility, very low tooling costs, and biocompatibility. Aluminum extrusions can be produced with very simple or complex designs as shown in the examples below.

Tooling costs are very low compared to injection molding or stamping. Extrusion dies for simple geometries cost around $750.00 and take 2 weeks to build. Hollow tube dies cost approximately $1,500.00 and take 3 weeks to build. Extrusion dies for the most complex designs can cost $4,000.00 and take 9 weeks.

| Design Complexity | Tooling Cost | Lead Time |

| Simple Solid Shape | $750.00 | 2 weeks |

| Hollow Tube or Shape | $1,500.00 | 3 weeks |

| Complex hollow design | $4,500.00 | 9 weeks |

Aluminum extrusions and tubing produced in alloys 6061, 6063 and 3003 are biocompatible. These alloys are used in many disposable medical devices. Medical device manufacturers such as Johnson & Johnson, Smith & Nephew and 3M Healthcare use aluminum extrusions in their designs. Aluminum ear tubes are a critical component of stethoscopes. Aluminum tubing is also used in disposable surgical tools such as circular staplers, trocars, and laparoscopic instruments. Extruded aluminum electrodes are used in electroporation cuvettes which are used in DNA research.

There is one myth to dispel about aluminum: exposure to aluminum causes Alzheimer’s Disease. In fact, aluminum has not been shown to cause Alzheimer’s according to the World Health Organization and The Alzheimer’s Association.

For over 30 years Profile Precision Extrusions has been manufacturing aluminum tubing and extruded aluminum shapes for the medical device, aerospace, and industrial markets. Contact us today to bring your design to life.