As the SARS-CoV-2 coronavirus spread globally in late 2019 and early 2020 the medical community was called upon as never before to care for the ill and to develop effective vaccines to protect humanity. Profile Precision Extrusions, in a very small way, played a part in supporting our medical industry customers helping to fight the pandemic. We have produced extruded shapes and aluminum tubing for the medical industry for more than twenty years. Some of the aluminum extrusions we produce are used in ventilators, stethoscopes, and UV light devices that kill the SARS-CoV-2 virus. We will continue to do our part to support our medical device industry customers helping to fight the pandemic.

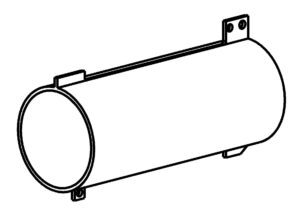

Heater Tubes

In March and April as infections and hospitalizations increased exponentially it was feared the nation would not have enough ventilators. The aluminum component shown below in part helps to heat and humidify air that is supplied to a patient on a ventilator. Not surprisingly, demand for these components increased in April and May as companies all over the world geared up to produce more of these life-saving machines. The aluminum is extruded in tube form, machined, and anodized.

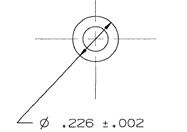

Stethoscopes

A stethoscope is a medical instrument used to listen to sounds, most typically from the heart and lungs. COVID-19 is a respiratory infection that can cause the lungs to fill with fluid and lead to pneumonia, which makes a tool like the stethoscope valuable and helpful in diagnosing respiratory issues. Profile has supplied extruded aluminum tubes for stethoscopes since 2008. As one of the most important diagnostic tools of physicians and nurses, it’s not surprising that demand surged in the late Spring. Profile increased production of extruded aluminum ear tubes to support the production of over 250,000 stethoscopes each month.

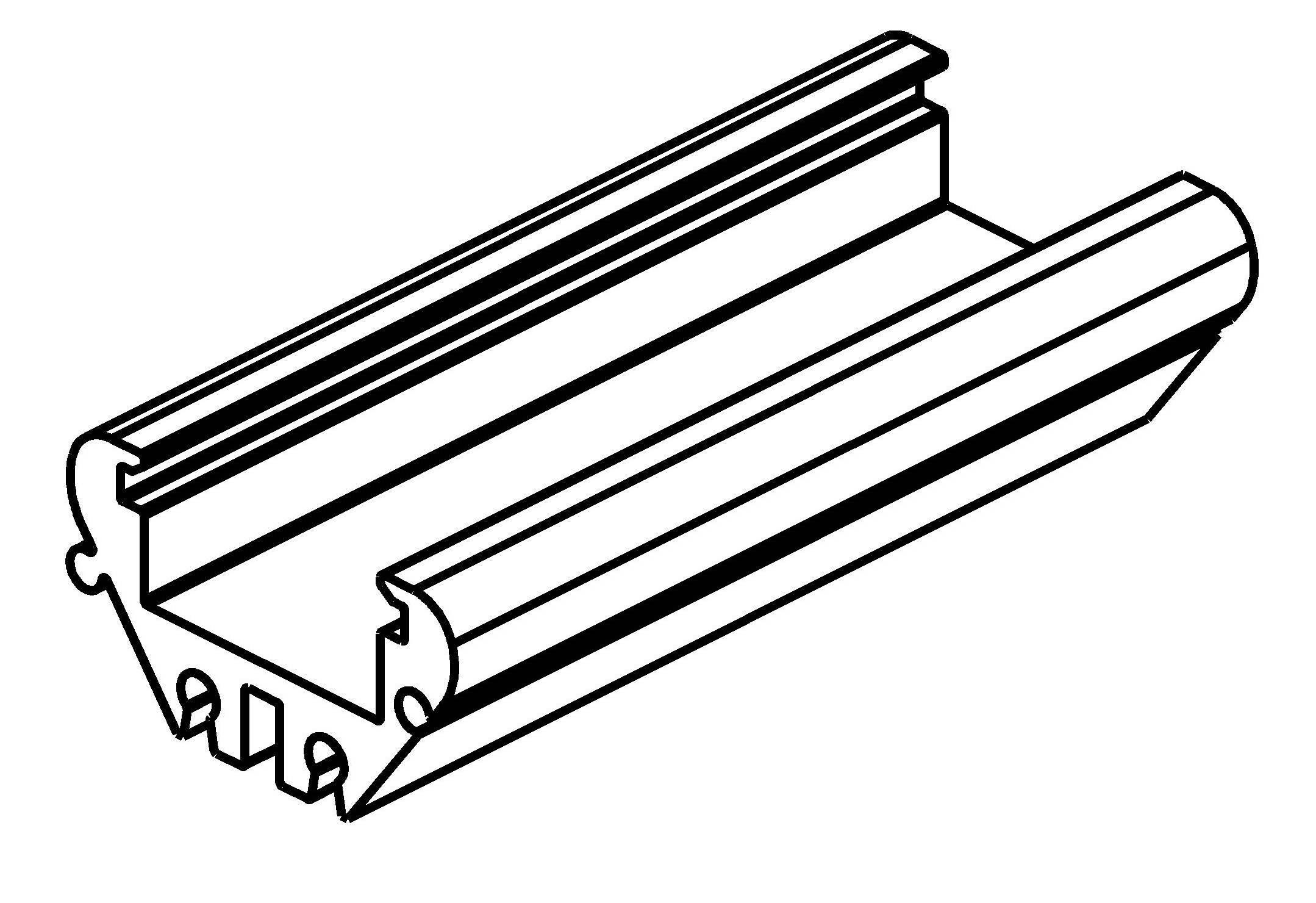

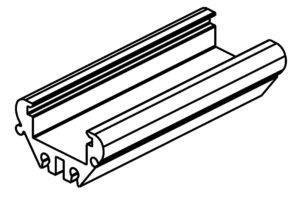

UV Lighting

Arguably the most impactful medical device product we have supplied in the fight against COVID-19 is an extruded aluminum heat sink. The extrusion holds LED diodes that create high-intensity UV light. The UV light waves react with a metallic catalyst and create ions which kill molds, bacteria, and viruses, including the SARS-CoV-2 coronavirus. The air purification system can be installed in central air systems of homes, hospitals, restaurants, gyms, commercial and government buildings. Demand has increased from 5,000 pieces per month to over 50,000 since late 2019. The aluminum heat sink holds an LED circuit board and dissipates the heat generated when the diodes are turned on.

All of the projects above started as prototypes. While many of these projects have been on a large scale, Profile Precision Extrusions does not have a minimum order size. We love to work with design engineers and entrepreneurs on new projects and new applications for aluminum shapes and tubing. To find how we can help you bring your idea to life, contact us today.