Miniature Aluminum Extrusions in Aerospace: Precision, Lightweight Solutions for Complex Designs

The aerospace industry demands components that are both lightweight and incredibly strong. Miniature aluminum extrusions have emerged as a crucial solution, providing precision and performance in applications where every gram matters. These specialized extrusions play a vital role in aircraft interior design, meeting critical engineering requirements while reducing overall weight.

Why Miniature Aluminum Extrusions Matter in Aerospace

Aluminum extrusions are widely used in aerospace due to their exceptional strength-to-weight ratio, corrosion resistance, and adaptability. Miniature aluminum extrusions take these advantages a step further, enabling intricate and lightweight designs that enhance passenger comfort in the cabin as well as fuel efficiency. Their applications range from interior galley and lavatory structures, LED lighting, seating, and avionics enclosures.

Profile Precision Extrusions has supplied extrusions to the aerospace industry for over 25 years and has been AS9100 D or ISO 9001 registered since 2012. Their rigorous quality control includes indefinite quality records retention, providing actual chemistry for each order, and testing and reporting actual mechanical properties. All of their aluminum alloys meet REACH and RoHS requirements, ensuring compliance with international safety and environmental standards.

Engineering Challenges and Manufacturing Precision

Manufacturing miniature aluminum extrusions for aerospace requires high-precision techniques to meet stringent industry standards. Tight tolerances, specialized alloys, and advanced fabrication methods ensure that these components meet the exacting demands of aerospace engineers. Key challenges include:

- Achieving uniform wall thickness in small-scale designs

- Meeting rigorous industry certifications, such as AS9100 D

- Balancing lightweight properties with structural durability

Performance Advantages in Aerospace Applications

Miniature aluminum extrusions offer several advantages that make them indispensable in modern aerospace engineering:

- Lightweight Design: Reducing aircraft weight leads to increased fuel efficiency and improved performance.

- High Strength and Durability: Aerospace-grade aluminum alloys ensure resilience under extreme conditions.

- Corrosion Resistance: Ideal for prolonged exposure to varying atmospheric conditions.

- Customization: Tailored extrusions can be designed to fit specific aerospace applications, reducing the need for additional machining and assembly.

Real-World Applications

Profile Precision Extrusions produces miniature aluminum extrusions for a variety of aerospace applications, including:

- LED Interior Lights: Lightweight and durable extrusions that enhance aircraft cabin lighting systems.

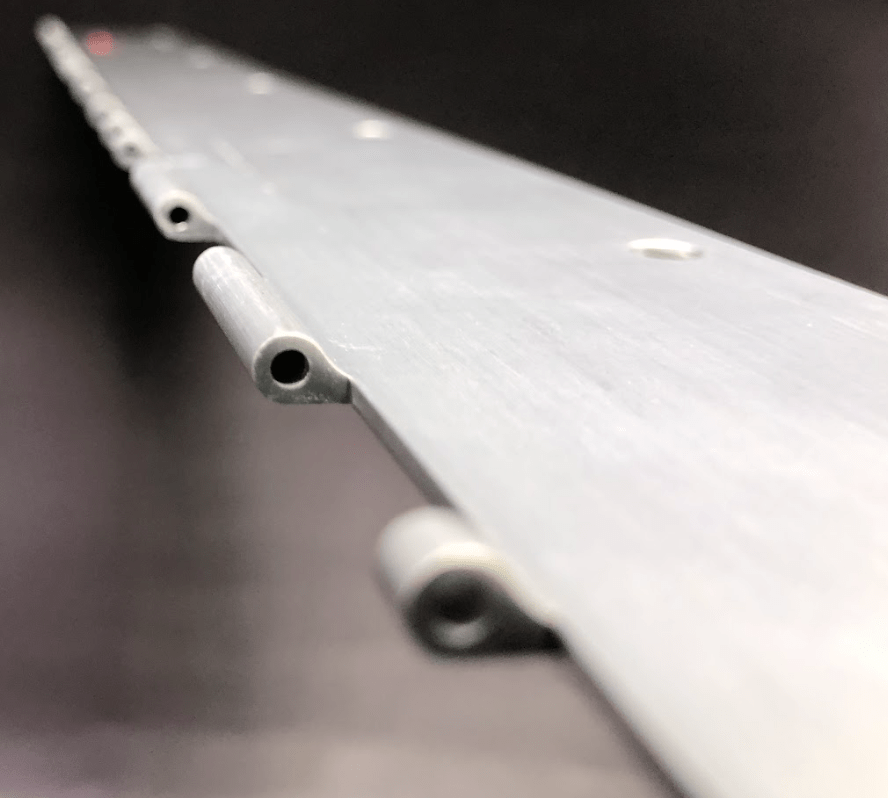

- Hinges for Galley and Overhead Bin Doors: Providing precision and durability for high-use components.

- Structural Extrusions for Lavatories: Ensuring stability and strength in confined aircraft spaces.

- Overhead Bin Brackets: Supporting the weight and function of critical storage compartments.

- Honeycomb Panel Pins: Joining aircraft honeycomb panels together.

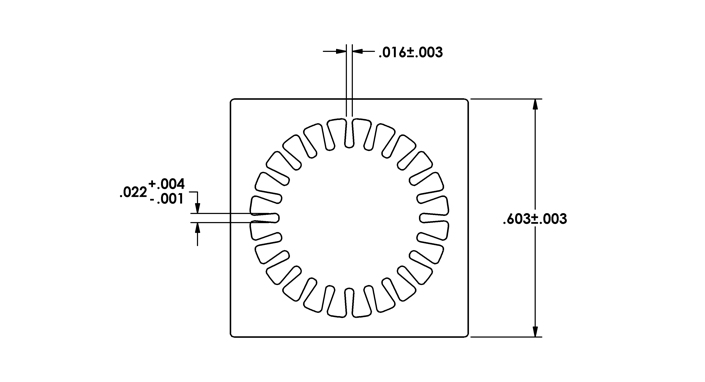

- Satellite Heat Pipe Extrusions: Complex designs that efficiently cool satellite electronics in extreme conditions.

Conclusion

The demand for high-precision, lightweight materials in aerospace continues to grow, making miniature aluminum extrusions an essential component of next-generation aircraft and spacecraft. With over 25 years of experience serving the aerospace industry, Profile Precision Extrusions provides highly specialized solutions that meet the industry’s most demanding requirements.

For high-quality, precision-engineered miniature aluminum extrusions tailored to your aerospace applications, contact Profile Precision Extrusions today. Our team specializes in delivering custom solutions that support the aerospace supply chain from commercial aviation to satellite manufacturing.