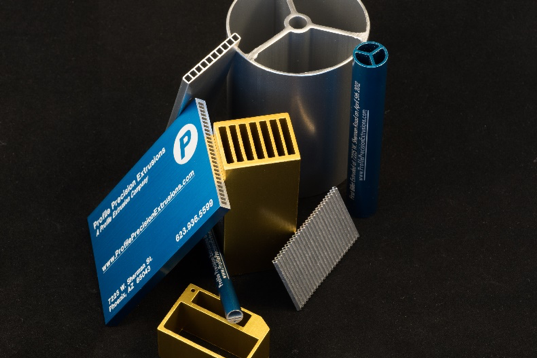

At Profile Precision Extrusions 5 of our top 10 customers anodize their aluminum extrusions. The benefits of anodizing are improved cosmetic appearance, abrasion resistance and preventing oxidation on the surface of the aluminum extrusion. A special type of anodizing called “hard coat” is specified when the surface needs to be wear resistant.

What is Aluminum Anodizing?

It is an electro-chemical process that forms a durable, oxide coat on the surface of aluminum extrusions. Anodizing is applied by immersing aluminum tubes or extruded shapes in a tank containing an acid-based electrolyte and an electric current is passed through the solution. The interaction of the electricity and electrolyte cause aluminum oxide to build up on the surface of the aluminum extrusion. The anodic coating prevents oxidation of the aluminum which normally occurs over time.

Many people know that Apple uses machined aluminum for the bodies of their iPhones, iPads, and MacBook laptops. Anodizing is used to improve the cosmetic appearance of these products. Not only do they look nice, they come in multiple colors. The coating also protects the metal from scratching when we drop the device, toss it in a backpack, or it goes sliding across the floor of your car when you forget to put it away properly.

Aluminum extrusions and tubing are anodized for industrial applications as well. Profile anodizes components used in yard equipment, aircraft, surgical devices and camera tripods. Anodizing protects the surface of the aluminum and keeps it looking nice for years of service. Some industrial applications are highly abrasive and the aluminum is subject to very high cycles of use. Hard coat anodizing, known as Type III coating, is a much thicker coating the wears very well over time in these environments. For those of you who’d like to learn more, Google “Type II anodizing Mil-A-8625” or “Type III anodizing Mil-A-8625”.

Profile Precision anodizes parts from ¼” long to 240” long. A wide variety of colors are available. In addition to the benefits above, anodized aluminum components are RoHS compliant, non-toxic, and very cost effective compared to other coatings. Contact us today to find out how aluminum anodizing can improve the appearance and durability of your aluminum extrusions.