Many customers contact Profile Precision Extrusions with an aluminum tube or extruded shape they have designed but are unsure what alloy and temper to select. We touch on alloys and…

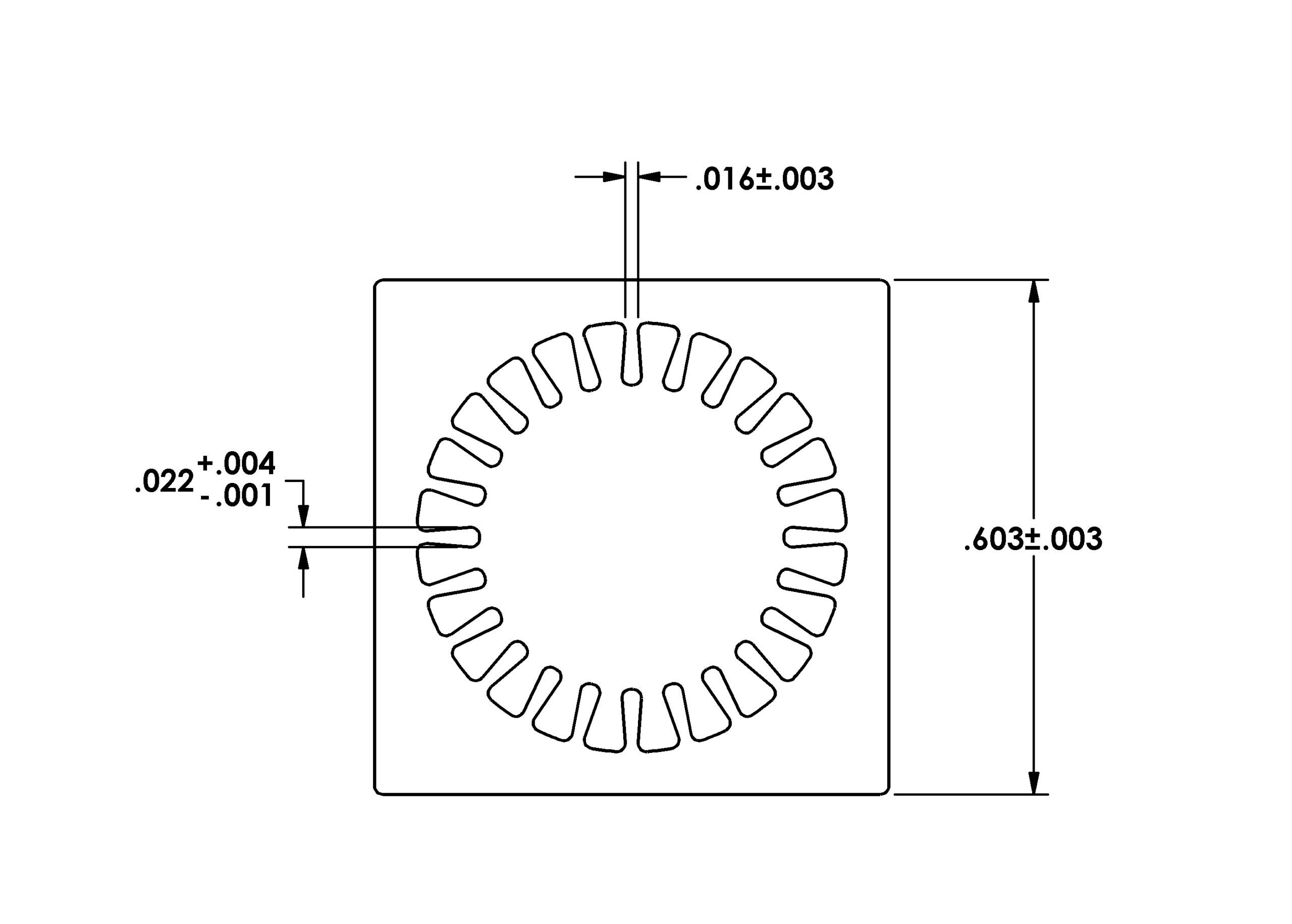

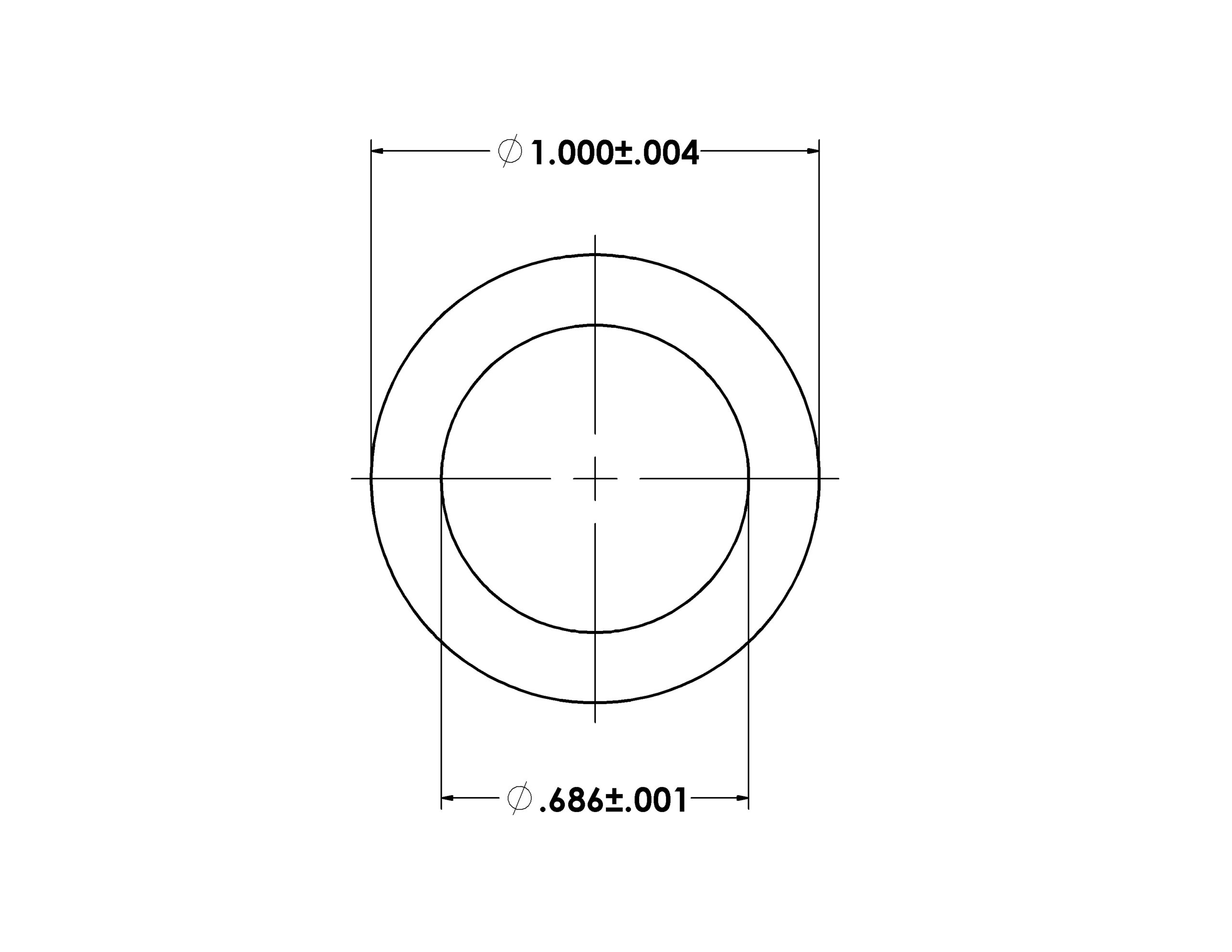

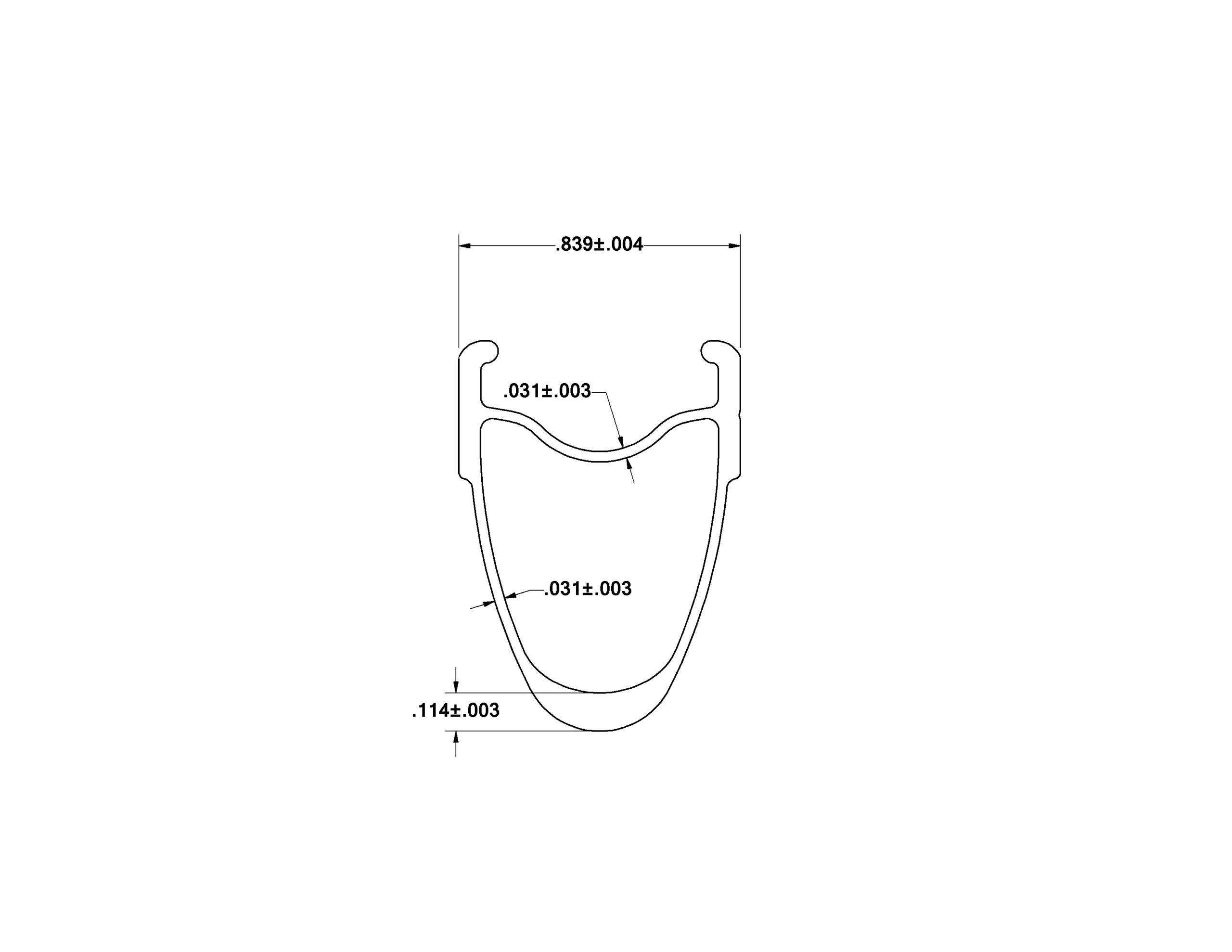

Expanding the Limits of Miniature Aluminum Extrusions

People ask us some great questions all the time: What is the thinnest wall you can extrude? I need ±.001" tolerances, can you hold that? What’s the largest part you…

3 Reasons to Pay More for Precision Miniature Aluminum Extrusions

The old adage “you get what you pay for” has been used and overused time and again. But like many cliches there’s an underlying truth. Every business has to provide…

Aluminum Tubing Forms: Seamless vs. Structural Part 2

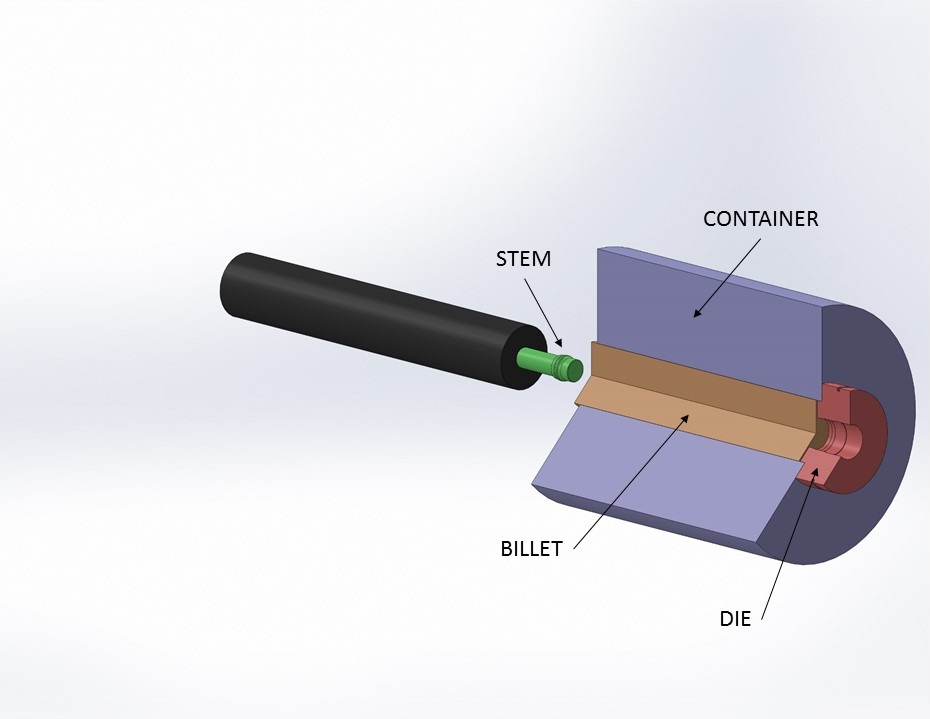

In our last blog we described how structural, or porthole, tubes are formed during the extrusion process. Structural tubing has weld seams that are a result of the extrusion billet…

Aluminum Porthole Tubing Forms: Seamless vs. Structural Part 1

Over 54% of the extruded aluminum Profile Precision manufactures each year has a hole in it, on purpose, and some have more than 1! The tube is commonly referred to…