Why Aluminum?

Aluminum is one of the most widely used materials in modern manufacturing—and for good reason. Known for its impressive strength-to-weight ratio, natural corrosion resistance, and recyclability, aluminum offers a unique set of advantages that make it a smart choice across many industries. When precision matters, miniature aluminum extrusions take those benefits even further.

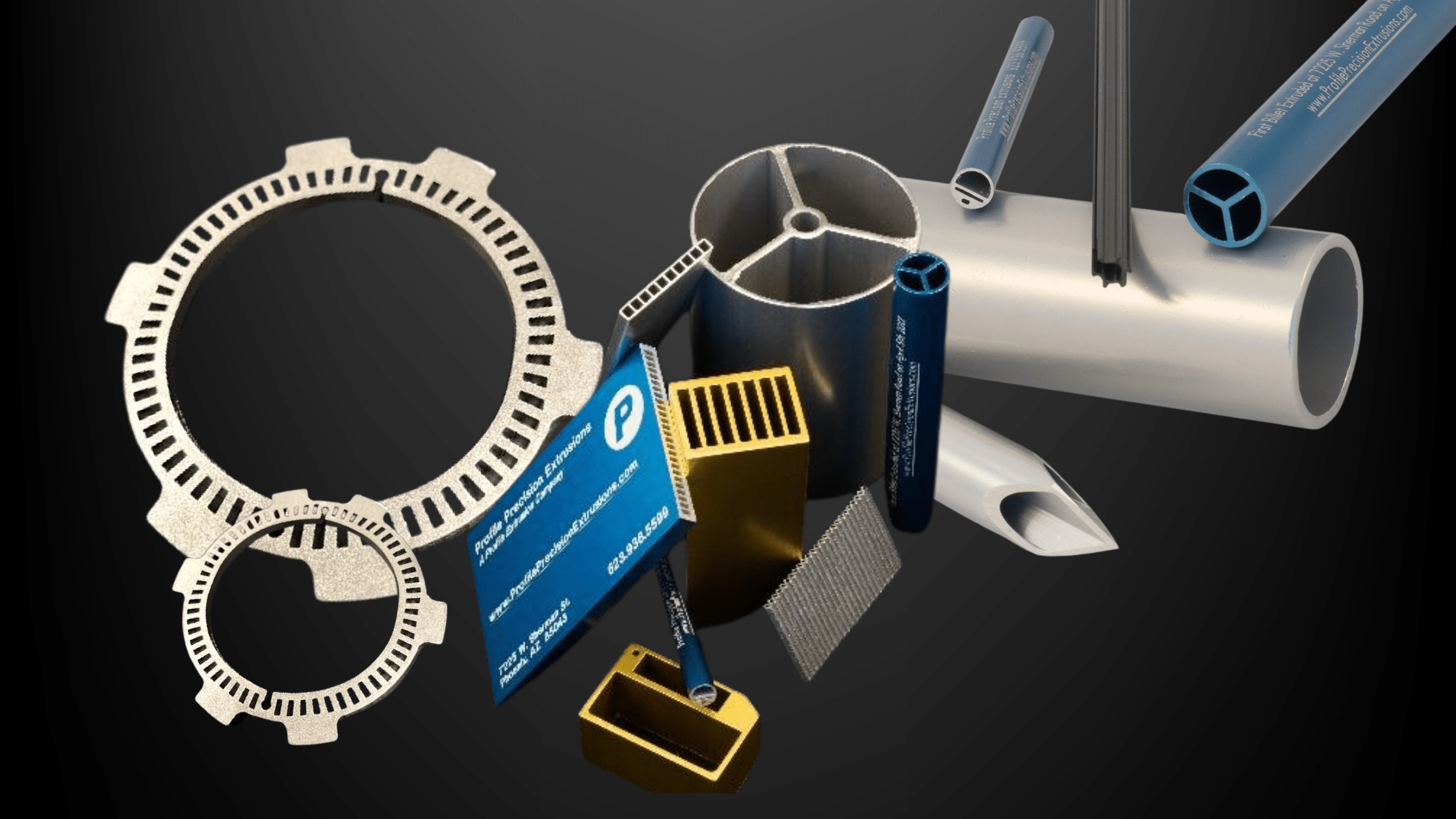

From medical devices to aircraft interiors, extruded aluminum shapes and aluminum tubing offer high-strength and lightweight designs in virtually unlimited customized forms.

Strength Without the Weight

One of aluminum’s most defining qualities is its strength relative to its weight. Aluminum weighs 1/3 as much as steel. This makes it ideal for applications where durability can’t come at the cost of added mass—like in satellite cooling system components, aircraft structural components and aircraft interiors. Gallies & lavatories and LED interior lighting all utilize precision miniature aluminum extrusions. Miniature aluminum extrusions offer engineers the ability to create strong, lightweight components while at the same time minimizing weight.

Precision for Complex Applications

Custom aluminum extrusions can be manufactured to extremely tight tolerances, which is critical in industries where exact fits and smooth finishes are essential. Whether it’s a surgical instrument or a precision-guided system component, aluminum extrusions can be designed to meet complex specifications with consistency and repeatability.

Corrosion Resistance That Lasts

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion—even in harsh environments. That’s a big advantage in industrial manufacturing or recreational products where components are exposed to moisture, chemicals, and temperature fluctuations. The result: longer product life and reduced maintenance over time.

Versatility in Design

Aluminum is highly formable, allowing it to be extruded into a wide variety of shapes and sizes—especially at a miniature scale. Whether you need a hollow tube, intricate channel, or completely custom profile, aluminum gives engineers the flexibility to bring creative and functional designs to life.

A Sustainable Solution

Aluminum is endlessly recyclable without losing its original properties. That makes it a key player in sustainable manufacturing practices. Using recycled aluminum requires just a fraction of the energy needed to produce new material, offering long-term environmental and economic benefits for companies committed to reducing their carbon footprint.

Trusted Across Industries

From life-saving medical tools to next-gen aerospace components, the benefits of aluminum material extend across countless applications:

- Aerospace: Lightweight structural supports, brackets, and thermal management systems

- Healthcare: Trocars, stethoscopes, and intricate geometry components for surgical tools used in heart, spinal, and rotator cuff surgeries.

- Industrial: Custom multi-void hollow designs for electrical sensors and two-piece telescoping drive shafts used in extendable commercial pruners

- Defense: High-precision heat pipes built for reliable, efficient cooling of satellite electronics

No matter the industry, aluminum extrusions bring strength, reliability, and efficiency to the table.

Final Thoughts

The benefits of aluminum material—lightweight strength, corrosion resistance, precision, and sustainability—make it an indispensable resource for engineers and manufacturers. At Profile Precision Extrusions, we specialize in creating miniature aluminum extrusions that support the most demanding applications across multiple industries.

Ready to Bring Your Design to Life?

If you’re looking to leverage the advantages of aluminum in your next project, we’re here to help. Contact us today for a custom quote and discover how our expertise can bring your vision to reality.