The aluminum extrusion industry is healthy as we enter a new decade. According to the Aluminum Association, total aluminum demand in North America was 28.3 billion pounds in 2018 (the last year data is available) compared to 25 billion pounds in 2015. Aluminum extrusions accounted for 5.5 billion pounds in 2018! That total is expected to grow as more aluminum extrusions are designed into battery electric vehicles (BEV’s), cars and trucks.

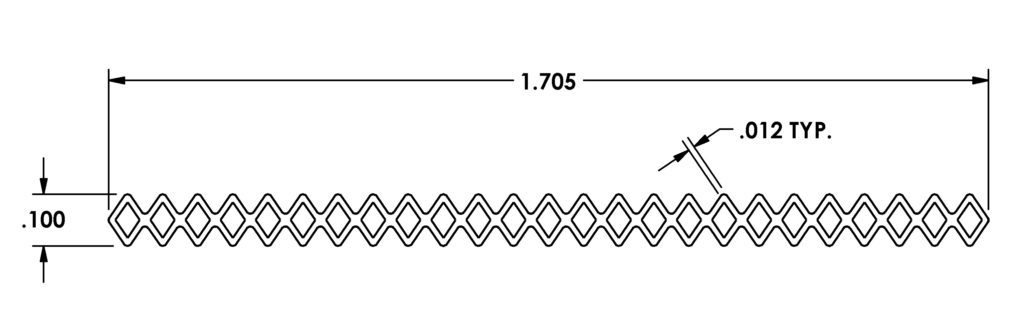

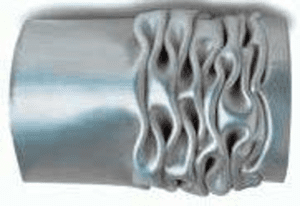

BEV engineers are taking advantage of aluminum’s high thermal conductivity to cool battery packs. Hollow extrusions are placed underneath or in between batteries and liquid coolant is run through them to keep battery temperatures optimal. Below is an example of a microchannel extrusion designed for cooling applications.

Aluminum’s high strength to weight ratio is also used by engineers as the framework for battery packs, dashboards, and bumpers. Their ultimate goal is to allow the vehicle to go as far as possible on a single charge. Aluminum extrusion usage in internal combustion engine cars and trucks continues to grow as well. According to a 2018 Ducker Worldwide survey 84 pounds of extrusions on average were used in cars in 1975. The forecast for 2025 is for each car to contain an average of 565 pounds! It’s clear that aluminum weight savings over steel components equals better gas mileage. Which can also make cars safer. According to the Aluminum Association, extrusions can absorb twice as much energy as steel.

The Future

Increasing usage of aluminum drives aluminum extruders, like Profile Precision Extrusions, to purchase larger extrusion presses and expand their factories. In a 2019 survey by The Aluminum Association found that large extrusion presses were running 90% of the time. The increasing demand for the production of commodity extrusions comes at the expense of small extrusion production. The same survey found small extrusion press utilization at less than 50%. Many 6” and 7” extrusion presses are being retired as a result. On January 31, 2020, the world’s largest extrusion company, Hydro Aluminum announced that it was exiting the small press extrusion business altogether.

For Profile Precision Extrusions the large producers chasing high volume projects is an opportunity. Engineers and designers working on new product development and small aluminum designs need someone to work with them. We believe these projects are important to future success and continue to seek out these types of opportunities. In fact, we are so committed to the miniature extrusion market that we are building a new 100,000 square foot factory. Its sole focus is to support the growing demand we see for small, precise aluminum shapes and extruded aluminum tubing.

Call us today! Profile Precision Extrusions would love to help with your aluminum project.