At a Glance: Key Aluminum Extrusion Industry Trends for 2026 Advanced manufacturing innovations—including precision automation and smarter prototyping workflows—will accelerate development cycles. Tariffs on imported prime aluminum, a necessary input…

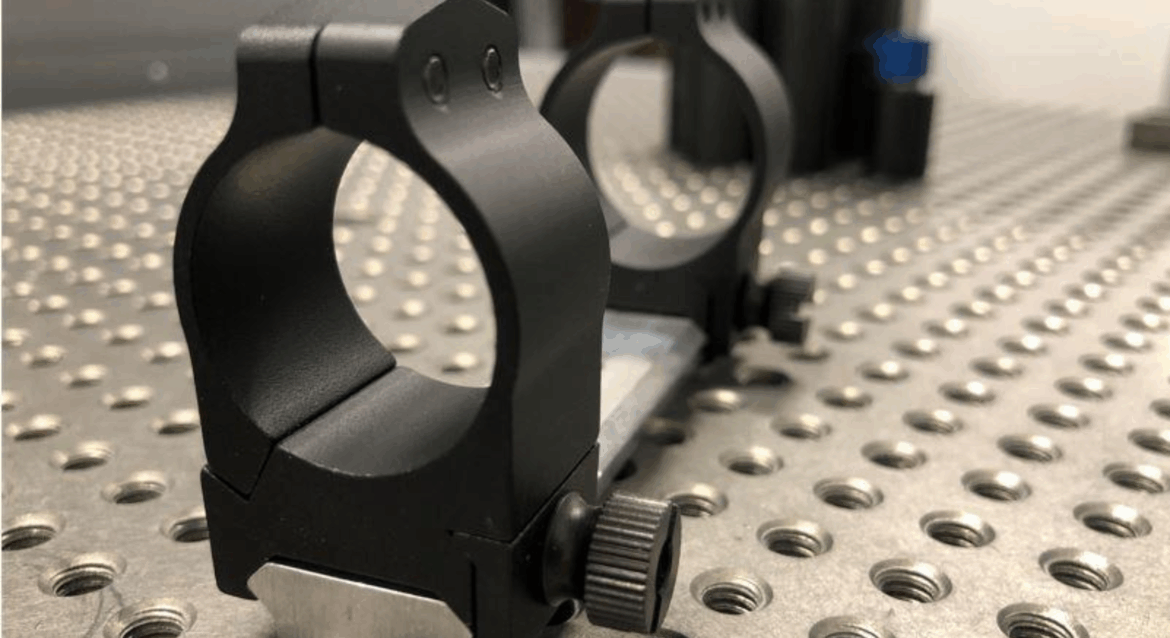

Precision Aluminum Extrusions: Applications in Firearms

At a Glance: Why Precision Aluminum Extrusions Excel in Firearms Lightweight Strength: Extruded aluminum delivers high strength-to-weight performance ideal for modern firearms accessories. Precision Machinability: Custom extrusions allow tight tolerances for components…

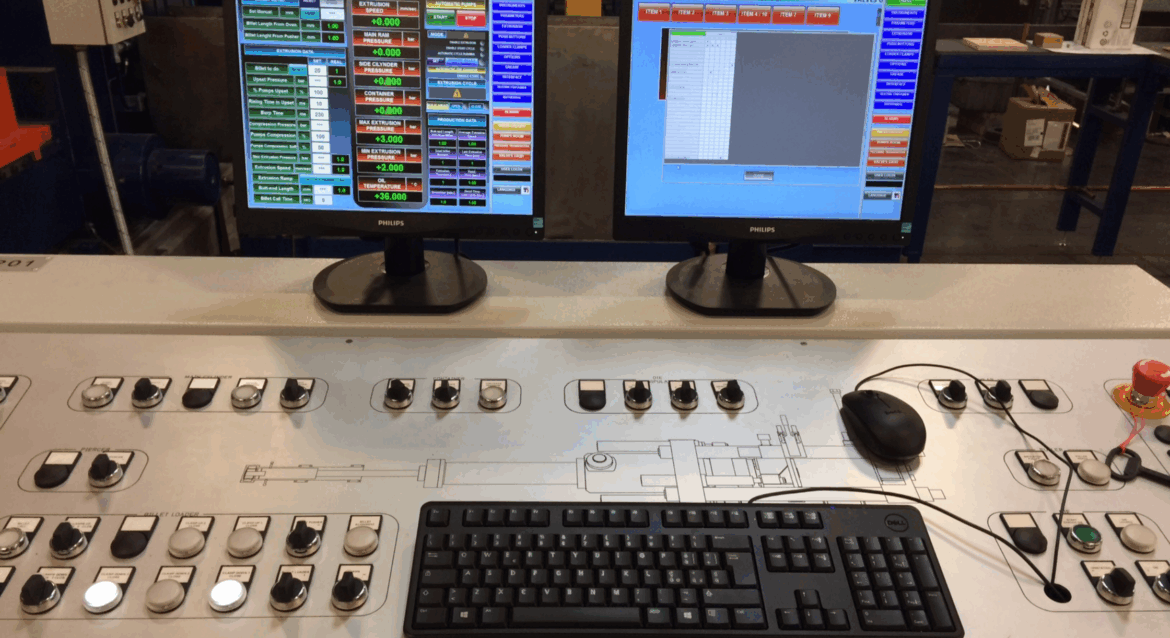

Quality Control Measures in Precision Aluminum Extrusion Manufacturing

Key Takeaways Aluminum extrusion quality control ensures consistency, precision, strength, and reliability. PPE verifies dimensions, tolerances, and surface finish through a variety of advanced inspection methods. Strict industry standards for…

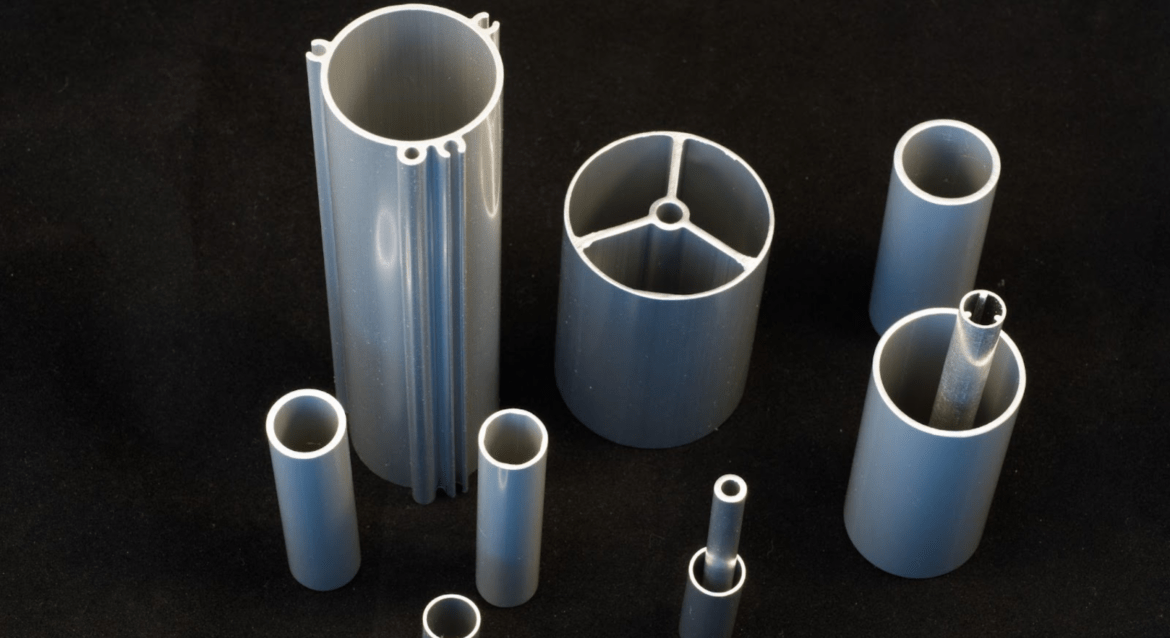

Designing with Aluminum Extrusions: Best Practices for Engineers

Define tolerances for critical features early in aluminum extrusion design early to avoid costly rework Consider material selection for extrusions based on performance needs Incorporate cost-effective aluminum extrusion design best practices to improve manufacturability. Reference PPE quick start guide. Partner…

What Drives Aluminum Extrusion Tooling Costs and How to Manage Them

At PPE most aluminum extrusion tooling costs fall between $1250 and $1950, depending on part complexity. Tooling charges include a custom die and sample parts, helping validate designs early. Design…