The aluminum extrusion process allows a designer an almost infinite number of geometric shapes to choose from. Custom aluminum extrusions and tubing range from simple angles to complex multi-void hollow shapes. The flexibility of aluminum extrusions helps the designer to save weight, save time and save money during the manufacturing process. Below are a few examples of the over 4000 aluminum extrusions Profile Precision has produced.

Not all designs can be extruded. Some common challenges are:

- Wall thickness is too thin for the alloy/temper chosen

- Dimensional tolerances desired are not attainable with the extrusion process

- Wall thicknesses varies too much from one area of the design to another

Please visit our Design Tips for more information.

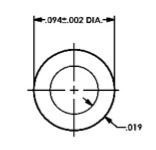

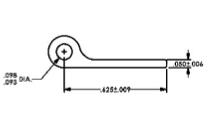

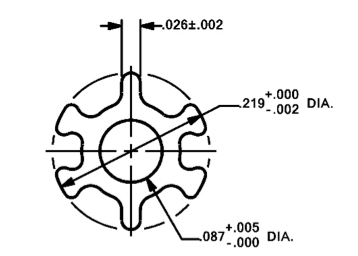

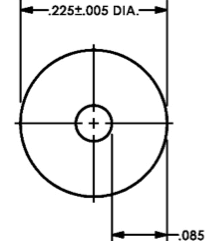

Custom aluminum extrusions can be produced to “near net” shape saving costly machining time compared to using a standard rod or bar stock. The first example from the medical device industry was originally produced out of stainless-steel tubing. A wire EDM was used to cut the round tube into the final shape. To increase volumes and reduce cost Profile was approached by the medical device company engineer who designed the part. His goal was to extrude the part to the final shape in 6061-T6. Utilizing a new extrusion die design concept Profile was able to successfully produce the part, reducing the part cost from over $20 per piece to less than $8.

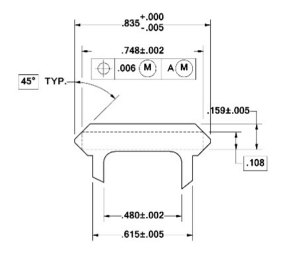

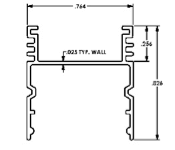

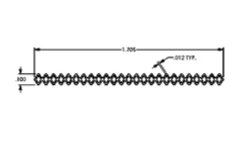

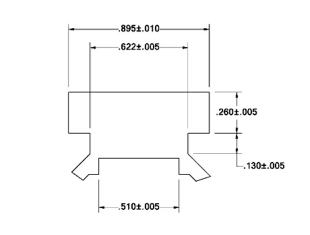

The second example is a Picatinny Rail from the firearms industry. These rails are used to affix telescopic scopes and other accessories to a firearm. The finished dimensions on the right were standardized by the US Military in the early 1990s and later adopted by the commercial firearms industry. Many commercial extrusion companies produce “pic rail” extrusions similar to the example on the left. That extrusion then has to be machined to the final dimensions on the right. Profile Precision takes the process one step further by extruding the pic rail to the finished dimensions. This saves the customer machining costs, reduces scrap cost, and shortens production lead time.

Contact us today with your custom aluminum extrusion project – 623.936.5599.