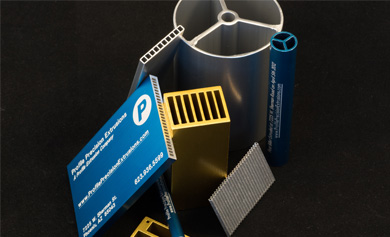

Profile Precision Extrusions has produced hundreds of extruded aluminum tube designs. Many have been straightforward round tubes. Others have been multi-void, thin wall designs. Multi-void designs are more challenging to produce. Designing these extrusions should take into consideration alloy and temper, wall thickness, and the dimensional tolerances required. Profile has a Design Tips page with more detailed information on the process of designing, submitting, and ordering aluminum extrusions.

Aluminum Alloys for Multi-void Extrusions

Aluminum alloys all extrude differently due to the percentage of other metals used to make each specific alloy. Higher purity alloys extrude more easily and are a popular choice for multi-void designs used for heat dissipation. Here is a handy chart that gives more information about popular aluminum alloys. 1100 and 3003 alloys are popular choices for thin wall multi-void extruded aluminum designs. The alloys can be extruded with wall thicknesses down to .015”. In addition, the alloys are very good at transferring heat. They are popular choices for designs used to cool electric vehicle battery packs and use in automotive radiators.

6061 and 6063 alloys are very popular alloys for aluminum extrusion designs. With both alloys, having equal wall thicknesses throughout the design gives the mill the best chance of successfully extruding your order. 6063 is easier to extrude in multi-void designs. It also tends to have a smoother surface and looks nicer after machining and anodizing. For applications requiring more strength or post extrusion machining, 6061 is the alloy of choice. While it typically does not look as nice when anodized, with the right combination of machining and deburring it can be made to have a very nice cosmetic finish.

Whether your design calls for a simple round or oval tube with thin walls, or an extruded multi-void hollow, contact Profile Precision Extrusions. We’re experts at helping take your design from the drawing board to production. Contact us and find out how we can help you lower your overall costs, increase quality, and save time by allowing us to manage the value chain for you. Profile Precision Extrusions would love to help with your unique challenge!