Your project might be a perfect candidate for aluminum extrusion. Or, it might not. How do you find out whether or not your aluminum extrusion idea is a good fit? A vast array of industries utilize aluminum shapes and extruded aluminum tubing. Understanding some of the basics of the process and conveying your requirements to a potential partner is crucial. In this blog, we will guide you through the process of fleshing out your idea and determining its suitability for aluminum extrusion manufacturing.

Understanding the Scope of Aluminum Extrusion

Aluminum extrusions find extensive use across diverse industries. Aluminum extrusions are used in the largest aircraft, EV’s, satellites, bicycles, and medical devices like stethoscopes, to name a few. Consider a few basics Profile Precision looks for when evaluating new designs:

-

Uniform Wall Thickness

- A design is much easier to produce if the wall thicknesses are uniform.

- A design is much easier to produce if the wall thicknesses are uniform.

-

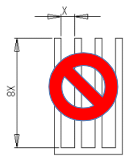

Tongue Ratio

- The ratio of the fin height to gap distance between the fins should be no more than 4:1. Higher ratios are possible, but require an indirect press which are uncommon in North America.

- The ratio of the fin height to gap distance between the fins should be no more than 4:1. Higher ratios are possible, but require an indirect press which are uncommon in North America.

-

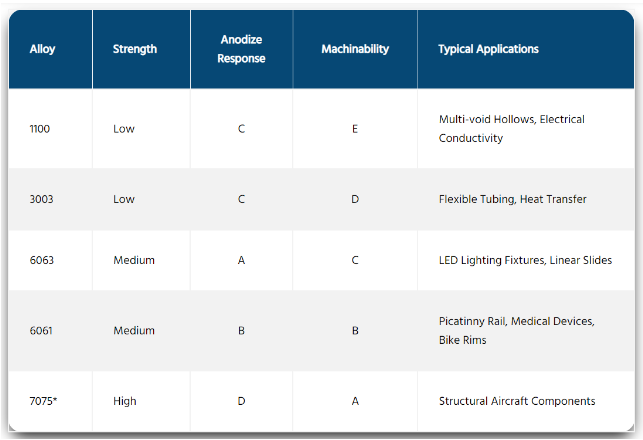

Aluminum Alloys

Consulting with Profile Precision Extrusions

At Profile Precision Extrusions, we have over 25 years of experience in reviewing designs for compatibility with the extrusion process. We’ve produced over 5,000 unique designs. While some ideas align perfectly, others may require modifications to fit our specific equipment. If your idea doesn’t match our capabilities, we’re more than willing to recommend other companies within our industry that can assist you. Our goal is to support your project’s success and foster a lasting partnership.

Optimizing Challenging Designs

Certain designs push the limits of what can be produced through extrusion. If your ideal design poses challenges, we will openly communicate this and suggest modifications to ensure compatibility with extrusion. In many cases, designers are willing to make the necessary adjustments to ensure successful extrusion. However, we understand that some projects may have low probabilities of success. We approach such cases with transparency and work together to explore alternative solutions.

Case Study: Overcoming Challenges

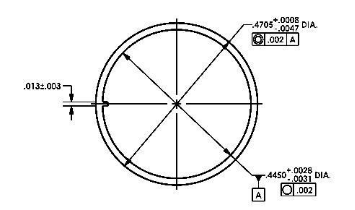

Recently, we encountered one of our most challenging extrusion designs for a consumer product. The design is a simple round tube. But as they say, the devil is in the details. The inside diameter tolerance generally does not pose a problem.

However, the addition of the .013” thick node on one side complicates production by making the design unbalanced. The aluminum will want to flow through the die at the node faster than the other areas. This can negatively impact the inside diameter circularity tolerance of .002” and the outside diameter concentricity tolerance of .002”.

The second challenge is the final wall thickness of .013”. Most extrusion mills would tell a designer it is not possible to extrude a design that thin. Profile has extruded some thin walls of .020” thick using 1100 and 3003 alloys. These alloys are the easiest ones to extrude. Adding to the challenge is the end user wanted 6063 alloy which looks nice after anodizing but is much harder to extrude than 1100 or 3003.

The third and final challenge is the surface roughness requirement of 12 – 28 Ra. The typical surface roughness of an extruded tube is 32 – 63 Ra. Of course, the customer wants a finish as close as possible to 12 Ra! That is a polished finish!

Case Study: Creating Solutions

To overcome the project challenges, we worked closely with two of our key vendors. One of our die makers specializes in dies that produce very precise tolerances, thin walls, and smooth surfaces. They developed the technology for the automotive radiator market. The dies have a special coating that is applied by vapor deposition. Even utilizing their specialized die, we could not achieve the thin walls and surface roughness the end user desired. Utilizing the special extrusion die we are able to extrude the tube with a wall thickness of .020”.

The second vendor we added to our solution centerless grinds extruded aluminum tubes for us. The tubes we normally centerless grind are used by our customers in their Swiss CNC machining. Centerless grinding reduces the outside diameter variation of the tube we extrude. By utilizing centerless grinding for this project we can extrude a tube with thicker walls. The vendor then centerless grinds off the outside until we achieve the wall thickness desired. They run the tubes through the process one more time and polish the outside diameter to the required surface finish.

Fleshing out the details of your idea is a crucial step before engaging a supplier for aluminum extrusion. By considering the wide range of applications and consulting experienced partners like Profile Precision Extrusions, you can determine the feasibility of your project. Embrace the challenges and be open to modifications that make your design more extrusion-friendly.

Together, we can bring your aluminum extrusion idea to life, ensuring its success and fostering a strong partnership for future projects. Contact us today for a free quote!