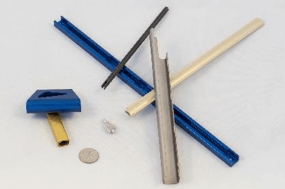

The benefits of aluminum extruded shapes and tube are known to many. According to the Aluminum Association, over 5.4 billion pounds were produced in North America during 2017. At Profile Precision, we have the pleasure each year to introduce this amazing metal to many engineers and designers who have not worked with it previously. According to our GM, there’s not a semester of Aluminum 101 in Engineering School.

Advantages of aluminum itself are a high strength to weight ratio, excellent machinability, easily recycled, corrosion resistant, and non-toxic. Extruded aluminum tubing and shapes have some additional advantages:

- Low tooling cost: $750 – $1500 for an extrusion die

- Easily formed: extrude to size rather than CNC machining

- Short production lead times:

- Four weeks for mill finish

- Five weeks for parts cut to 60” or less

- Six weeks for anodize finish

- Six weeks for machined parts

- Cosmetically attractive: can be anodized, painted, brushed or polished

If you’d like aluminum extrusion design tips, visit Profile Precision Extrusions https://profileprecisionextrusions.com/design-tips/. We have successfully produced over 4000 designs. We would be happy to help bring yours to life. We have no minimum order size, offer free design assistance and offer many value-added services. Profile has a simple philosophy: We will exceed your expectations or work until we do. Contact us today!