Lead time times can vary significantly within the aluminum extrusion industry. Current lead times for some specialty products are: Drawn seamless aluminum tubing 50-60 weeks Structural extrusions in 7xx &…

Advantages of Aluminum for Aircraft Interiors

Aluminum is used extensively in the production of modern aircrafts. According to the Aluminum Association, aluminum comprises 80 percent of the weight of typical passenger aircraft. Many different forms of…

The Benefits of Choosing Profile Precision Extrusions

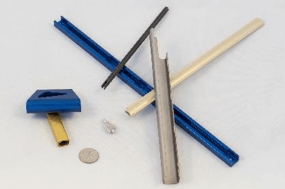

The benefits of aluminum extruded shapes and tube are known to many. According to the Aluminum Association, over 5.4 billion pounds were produced in North America during 2017. At Profile…

Aluminum Extrusion Manufacturing Process part 2 of 2

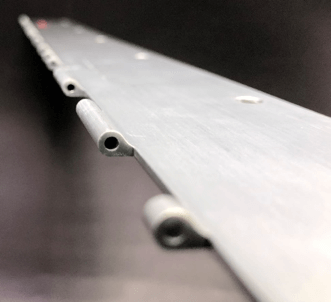

Our last blog focused on the initial steps in the aluminum extrusion manufacturing process. The design is finalized, extrusion die fabricated, a production plan developed, an aluminum billet is heated…

Aluminum Extrusion Manufacturing Process part 1 of 2

Many people who describe the aluminum extrusion manufacturing process use a child playing with Play-Doh as an analogy. It’s a good one. A child rolls a little ball of dough…